D2 tool steel is a popular choice for many welders because of its high carbon content and wear resistance properties. However, D2 tool steel is also notoriously difficult to weld because of its high chromium content. In this article, we’ll take a look at some of the best ways to weld D2 tool steel.

- D2 tool steel is an air-hardening, high carbon, and high chromium alloy

- It has excellent wear resistance and toughness properties making it ideal for use in long-running industrial applications

- In order to weld this type of steel, a special rod must be used that is compatible with the high carbon content

- The welder must also take care to avoid welding over contaminants such as rust or paint, as these can weaken the final weld joint

- Once all preparatory work is complete, the welding process itself can begin

- First, a tack weld should be made at the corners of the joint to be fused together

- Next, a series of short beads should be run along the length of the seam while maintaining a low heat input to prevent warping or distortion of the metal

- Finally, the entire weld bead should be gone over once more to ensure even coverage and penetration before allowing it to cool completely

D2 Welding Rod

D2 welding rod is a type of electrode used in stick welding. It is made of high-carbon steel and is used to weld low-carbon steels. This electrode has a good reputation for being able to produce strong, durable welds.

It can be used on a variety of different metals, including cast iron, stainless steel, and tool steel.

D2 Tool Steel Hardness

D2 tool steel is a versatile high-carbon, high-chromium, air-hardening tool steel that is characterized by a relatively high attainable hardness and numerous, large, chromium-rich alloy carbides in the microstructure. These carbides provide good levels of wear resistance when hardened sufficiently. Additionally, D2 offers excellent corrosion resistance when maintained properly.

Heat Treatment of D2 Tool Steel Pdf

D2 tool steel is a versatile high-carbon, high-chromium alloy that exhibits excellent wear resistance and toughness. As a result of its high carbon content, D2 tool steel is often used in applications where edge retention is critical. In addition, the chromium content of D2 tool steel provides good corrosion resistance.

D2 Tool Steel Heat Treatment

D2 tool steel is a high carbon, high chromium alloy that is often used for making cutting tools and wear-resistant parts. It has excellent hardenability and wear resistance, but it can be difficult to work with due to its high carbon content.

The best way to heat treat D2 tool steel is to first preheat it to between 800-900 degrees Fahrenheit, then raise the temperature slowly up to between 1475-1525 degrees Fahrenheit.

Hold the steel at this temperature for about an hour before quenching in oil or air cooling.

D2 Tool Steel Knife

D2 tool steel knives are some of the most popular and durable knives on the market. This high-carbon, high-chromium steel is often used in industrial applications where wear resistance and toughness are required. It is also a common choice for knife making due to its excellent edge retention and corrosion resistance.

D2 tool steel contains around 1% carbon and 12% chromium. The addition of vanadium gives it better wear resistance and edge retention than other steels with similar carbon content. It is typically heat treated to achieve a Rockwell hardness of 60-62 HRC.

Despite its many advantages, D2 tool steel does have some drawbacks. It is difficult to sharpen and can be prone to chipping if not used properly. It is also one of the more expensive knife steels on the market.

If you’re looking for a durable and long lasting knife, then a D2 tool steel knife is a great option. Just be aware of its limitations and you’ll be able to enjoy all that this amazing steel has to offer.

D2 Hardness before Heat Treat

D2 is a high-carbon, high-chromium tool steel that has been hardened by air cooling. It is used for making cutting tools and molds. D2 has a higher carbon content than other tool steels, which gives it better wear resistance.

However, this also makes it more susceptible to cracking. D2 should be heat treated before use to ensure that it will not crack during use.

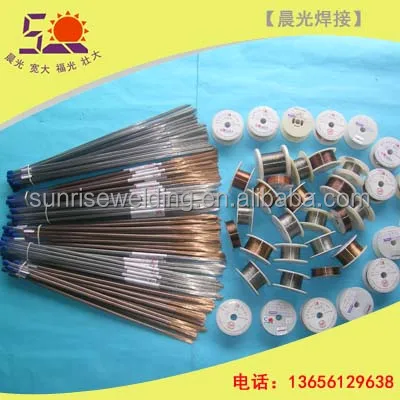

Tool Steel Mig Wire

If you’re looking for a high quality mig wire for welding tool steel, you can’t go wrong with our Tool Steel Mig Wire. This mig wire is designed specifically for welding tool steel and other high strength steels. It’s made from a special alloy that provides excellent arc stability and low spatter, making it ideal for use in robotic or automated welding applications.

Plus, it has a clean, smooth finish that will give your welds a professional look.

Credit: www.alibaba.com

Can Tool Steel Be Welded?

Yes, tool steel can be welded. In fact, most types of steel can be welded. However, welding tool steel requires special techniques and care.

Here are a few tips for welding tool steel:

-Use a low hydrogen electrode. This will help prevent cracking in the weld.

-Weld in short bursts. Overheating the metal can cause it to lose its hardness.

-Be sure to anneal the metal before and after welding.

This will help relieve stress in the metal and prevent warping.

Does D2 Steel Need to Be Hardened?

Different types of steel have different properties, and therefore require different treatments in order to achieve the desired results. D2 steel is a high carbon, high chromium tool steel that is often used for making knives and other cutting tools. It is a tough steel that can be difficult to work with, but it can also be very rewarding once you get the hang of it.

In order to get the most out of D2 steel, it is important to know how to harden it properly.

D2 steel can be hardened in two ways: through heat treatment or by cold working. Heat treatment involves heating the steel up to a specific temperature and then cooling it down slowly in order to achieve the desired hardness.

This method is often used when large parts need to be hardened, as it evenly distributes the heat throughout the metal. Cold working, on the other hand, involves manipulate the metal at room temperature in order to harden it. This method is often used for smaller parts or for precision work where heat treatment would not be ideal.

No matter which method you choose, hardening D2 steel correctly will result in a tough, durable cutting edge that will hold up well under use.

What is D2 Tool Steel Used For?

D2 tool steel is a popular choice for many different applications, including:

-Making high-strength cutting tools (such as drill bits and end mills) -Creating cold work dies (such as punches and stamping dies)-Forming wear-resistant parts (such as bearings and gears) D2 tool steel is known for its high level of wear resistance, making it ideal for applications where extended tool life is desired. It also has good toughness and ductility, meaning it can withstand heavy use without breaking or becoming deformed.

Additionally, D2 tool steel has excellent dimensional stability, meaning it holds its shape well during heat treatment.

How Do You Harden D2 Tool Steel?

D2 tool steel is a high carbon and high chromium alloy that is often used for making knives and other cutting tools. It is a very tough and durable steel, but it can be difficult to work with if you don’t know how to properly harden it. In this article, we will go over the steps you need to take in order to harden D2 tool steel correctly.

The first step is to heat up the steel. You will want to heat it until it is a dull red color. If you have a torch, you can use that, but you need to be careful not to overheat the steel or else it will become too brittle.

Once the steel is heated up, you need to quench it in oil.

You need to be careful when quenching as well because if the oil is too cold, the steel will crack. After quenching, you need to temper the steel by heating it up again and then cooling it down slowly.

This will help relieve some of the stress from the quenching process and make thesteel tougher.

Now your D2 tool steel should be hardened and ready for use!

What is D2 Tool Steel?

Conclusion

D2 tool steel is a popular choice for many knife makers and other metalworkers, but can it be welded? The answer is yes, but there are some things to keep in mind. D2 is an air-hardening steel, so it must be heated slowly and cooled quickly to avoid cracking.

It also has a high carbon content, which can make welding difficult. However, with the right precautions and techniques, welding D2 tool steel is possible.