Pulsed-arc welding systems use an arc that is rapidly pulsed on and off to weld metal. These systems were developed in the 1970s and are now used extensively in industry. Pulsed-arc welding has many advantages over traditional welding techniques, including greater control of the weld pool, reduced spatter, and lower heat input into the workpiece.

This makes it possible to weld thinner materials with less distortion.

Pulsed-arc welding systems are a type of welding that uses an electric arc to weld metal. This method is used for both heavy and light gauge metals. The first pulsed-arc welding system was developed in the early 1940s.

In the Pulsed-Arc Metal Transfer Current Cycle

Pulsed-arc metal transfer current cycle is a process that helps to improve the efficiency of welding. This method uses an arc that is created by applying a current to the electrode. The arc is then extinguished and reignited at a high frequency.

By doing this, it helps to reduce the amount of time that the electrode is in contact with the workpiece. This method can be used for both ferrous and non-ferrous metals. When pulsed-arc metal transfer current cycle is used, it creates less spatter and provides a higher quality weld.

In addition, this process helps to increase productivity because it can weld multiple passes in a shorter period of time.

When was Arc Welding Invented

Arc welding is a type of welding that uses an electric arc to create heat. The heat generated by the arc melts the metals being joined, and the molten metal forms a weld. Arc welding is one of the most common types of welding, and it can be used to join a variety of metals.

The history of arc welding dates back to the late 1800s, when French engineer Auguste de Méritens developed an early version of the process. In 1885, two American inventors, C.L. Coffin and C.J. Blodgett, filed patents for their own versions of arc welding. These early versions of arc welding were not very efficient, and they were not widely used.

In 1906, Russian inventor Nikolay Slavyanov patented an improved method of arc welding that used a carbon electrode. This was the first time that a non-metal electrode had been used in arc welding, and it made the process much more efficient. Slavyanov’s method quickly became popular in Russia and other European countries.

In 1912, Englishman Harold Pomeroy patented a further improvement to Slavyanov’s design, which added shielding gas to protect the weld from atmospheric contamination.

Gma Welding Machines Have ____ Duty Cycle.

If you’re a welder, then you know that having a dependable welding machine is essential. And when it comes to finding a welding machine that’s both durable and affordable, there’s no better option than a GMA welding machine. But what exactly is the duty cycle of a GMA welding machine?

The duty cycle of a welding machine is the amount of time that the machine can be used continuously without needing to be shut off to cool down. For example, if a welding machine has a 30% duty cycle, that means it can be used for three minutes before it needs to be turned off for one minute to cool down. So how does this apply to GMA welding machines?

Well, all GMA welding machines have 100% duty cycles. That means they can be used continuously without ever needing to be shut off! This makes them ideal for welders who need to get the job done quickly and efficiently.

So if you’re in the market for a new welding machine, make sure to check out the selection of GMA welders available. With their 100% duty cycles, they’ll help you get the job done right – and on time!

When was Welding First Used on Ships

Welding was first used on ships in the early 20th century. The process was used to join together metal plates to create a stronger, more durable hull. This new method of construction allowed for the creation of larger and more complex vessels.

Today, welding is an essential part of shipbuilding and plays a vital role in ensuring the safety of both passengers and crew.

When was Tig Welding Invented

Tig welding is a popular welding process that uses an electrode to create an arc between the workpiece and the filler metal. The electrode is made of tungsten, which has a high melting point and is resistant to corrosion. Tig welding was invented in 1941 by Russell Meredith.

History of Welding Timeline

In the late 1800s, welding was developed as a joining process for iron and steel. This new method of joining metals revolutionized the construction industry and quickly became an essential part of manufacturing. Today, welding is used in a variety of industries to join everything from small components to large structures.

The history of welding can be traced back to the early 1800s, when Sir Humphry Davy discovered that an electric arc could be used to weld metals together. In 1801, he published his findings in a paper entitled “On Some Chemical Agencies of Electricity”. Davy’s work laid the foundation for future developments in welding technology.

In 1885, Auguste de Méritens patented the first ever gas-shielded welding process. This marked a major milestone in the history of welding, as it paved the way for modern day processes such as MIG and TIG welding. De Méritens’ invention was later refined by other scientists and engineers, leading to the development of more efficient and effective gas-shielded welding processes.

Today, there are many different types of welding processes available for use. Each has its own advantages and disadvantages, which makes it important to select the right process for each particular application.

When was Welding Invented

Welding is a process of joining two pieces of metal together by using heat. The history of welding goes back to the time when people first started working with metals. The earliest evidence of welding was found in the Bronze Age, around 3,000 BC.

In those days, welders used forge welding to join pieces of metal together. The first recorded instance of welding was done by blacksmiths in China who were trying to join iron and steel together. They heated the metals until they were red-hot and then hammered them together.

This process was known as “forge welding”. It was not a very strong joint, but it was good enough for many purposes. In 1885, a man named Oscar Kjellberg invented a new type of welding called “arc welding”.

Arc welding uses an electric arc to generate heat for joining metals together. This made it possible to weld much thinner pieces of metal than before, and it also produced stronger joints. Arc welding is still used today for many applications.

____ is a Series of Ridges Cut into the Groove.

Rifling is the process of adding spiral grooves to the inside of a gun barrel. These grooves give the bullet a spin as it travels down the barrel, which makes it more accurate and stable in flight. Rifling has been around for centuries, but it wasn’t until the 19th century that it became widespread in firearms.

The first recorded use of rifled gun barrels dates back to 1498, when German marksmen used them to shoot at targets at long range. However, it wasn’t until the mid-19th century that rifled barrels became common in small arms. The British army introduced rifles with rifled barrels in 1853, and they quickly became standard issue for most militaries around the world.

Rifles were not the only type of firearm to benefit from rifling. In the American Civil War, both Union and Confederate forces used rifled artillery pieces with great success. The accuracy and range of these guns far exceeded anything that had come before, and they played a key role in many battles.

Today, all modern firearms are equipped with rifled barrels, and the technology continues to evolve. New materials and manufacturing techniques have made today’s gun barrels more accurate than ever before.

Credit: www.mtwmag.com

When was Pulsed Arc Welding Invented?

Pulsed arc welding was invented in the early 1970s. It is a type of welding that uses an electric current to create an arc between two pieces of metal. The arc is then pulsed with short bursts of current, which heats the metal and causes it to weld together.

When was Pulse Mig Invented?

Pulse MIG was invented in the early 1970s. It was developed as a way to improve the quality of welding by reducing the amount of spatter and improving weld penetration.

What is Pulse Arc Welding?

Pulse arc welding is a type of welding that uses an electric arc to weld two pieces of metal together. The arc is created by an electrode that is connected to a power source, and the heat from the arc melts the metal, which joins the two pieces together. Pulse arc welding can be used for a variety of metals, including steel, stainless steel, aluminum, and titanium.

It can be used to weld thin sheets of metal together, or to join thicker pieces of metal. Pulse arc welding can also be used to weld dissimilar metals together. Pulse arc welding is a fast and efficient way to weld two pieces of metal together.

It produces strong and reliable welds, and can be used in a variety of applications.

Who Invented Plasma Arc Welding in 1957?

In 1957, a man named Robert Gage developed plasma arc welding. It is a form of welding that uses an electric arc to create heat, which then melts the metal being worked on. The process is similar to other forms of welding, such as TIG welding, but with the addition of a plasma torch.

Plasma arc welding has many advantages over traditional methods, including higher speeds and greater accuracy.

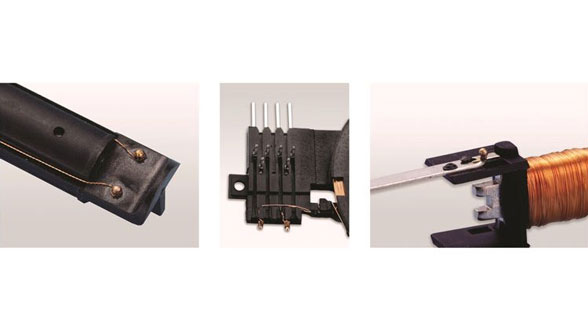

Pulsed arc fillet weld

Conclusion

Pulse-arc welding systems were developed in the 1950s. The technology was originally used for welding metals such as stainless steel and aluminum. Today, pulse-arc welders are used for a variety of applications, including welding plastics and other non-metallic materials.