A2 tool steel is a versatile, all-purpose tool steel that can be used for a variety of applications. It is often used for welding because it has a high carbon content, which makes it resistant to heat and wear. When welding A2 tool steel, it is important to preheat the metal to the proper temperature to ensure a strong weld.

If you’re looking to weld A2 tool steel, you’ll need to preheat it first. But what temperature should you preheat it to?

The answer depends on a few factors, including the thickness of the steel and the welding process you’re using.

However, as a general rule, you should preheat A2 tool steel to between 1200 and 1600 degrees Fahrenheit before welding.

This will help ensure that the steel doesn’t crack or warp during the welding process. Just be sure not to overheat the steel, as this can also cause problems.

If in doubt, err on the side of caution and preheat to a lower temperature rather than a higher one.

Welding M4 Tool Steel

Welding M4 Tool Steel

M4 tool steel is a high speed steel that is often used in cutting tools. It is a tough, durable alloy that can withstand high temperatures and has a high resistance to wear.

When welding M4 tool steel, it is important to use the correct filler metal and preheat the material properly.

M4 tool steel is typically used for cutting tools such as end mills and drill bits. It can also be used for knives, shear blades, and punches.

The high speed steel is tough and resistant to wear, making it an ideal choice for these applications. When welding M4 tool steel, it is important to use the correct filler metal. A common mistake when welding this material is to use too much heat, which can cause the material to warp or crack.

It is also important to preheat the material before welding to prevent cracking.

A2 Tool Steel Heat Treat Chart

A2 tool steel is a versatile, all-purpose tool steel that has good hardness and wear resistance. It is often used for making knives, as it holds an edge well and is easy to sharpen. A2 can be heat treated to a variety of different hardness levels, depending on what properties you need for your project.

The following chart shows the approximate hardness that can be achieved with different heat treatment methods:

Method | Approximate Hardness (HRC)

——-|————————–

Annealed | 30-35

Softened | 45-50

Hardened | 55-60

Welding Mild Steel to Tool Steel

Welding is a way of joining two pieces of metal together by using heat and pressure. The most common metals that are welded are mild steel and tool steel. There are many different ways to weld these metals together, but the most common method is with an oxyacetylene torch.

Mild steel is a type of carbon steel that contains less than 0.3% carbon. It is also known as low-carbon steel or plain-carbon steel. Tool steel is a type of carbon steel that contains between 0.6% and 1.7% carbon, as well as other alloying elements such as manganese, chromium, tungsten, and vanadium.

There are several reasons why you might want to weld mild steel to tool steel. For example, you might need to repair a damaged piece of machinery or equipment that is made from tool steel. Or, you might be fabricating a new piece of equipment that requires both types of metal.

Whatever the reason, it’s important to know how to properly weld these two metals together. Here are some tips for welding mild steel to tool steel: – Use an oxyacetylene torch with acetylene gas and oxygen gas (this is the most common method)

– Adjust the gas flow rate so that the oxygen flow rate is about twice the acetylene flow rate – Use a tip size that is appropriate for the thickness of metal being welded – generally speaking, thicker metal will require a larger tip size – Preheat the area to be welded with your torch before beginning the actual welding process

– Weld in short bursts rather than one long continuous bead – this will help prevent warping and distortion – Allow the area to cool slowly after welding – do not quench it in water!

Heat Treating A2 Tool Steel at Home

A2 tool steel is a versatile, all-purpose tool steel that can be used for a variety of applications. It is typically used for making tools and dies, but it can also be used for other purposes such as knife blades and drill bits. A2 tool steel is easy to heat treat at home, and with the right equipment, it can be done relatively quickly.

To heat treat A2 tool steel, you will need a furnace or kiln that can reach temperatures of 1900-2100 degrees Fahrenheit. The steel should be heated slowly and evenly to avoid cracking or warping. Once the desired temperature is reached, the steel should be held at that temperature for 1-2 hours before being cooled down gradually.

If you are looking to harden your A2 tool steel, quench it in oil or water once it reaches a temperature between 1800-1900 degrees Fahrenheit. For maximum hardness, temper the steel immediately after quenching by reheating it to 350 degrees Fahrenheit and then cooling it down gradually.

Tool steels like A2 can be tricky to heat treat correctly, but with careful attention paid to heating and cooling rates as well as quenching media, it is possible to achieve excellent results at home.

With a little practice, you’ll be able to heat treat your A2 tools just like the pros!

Welding Tool Steel With 7018

When it comes to welding tool steel, there are a few different options that you have. One of those options is to weld with 7018. In this blog post, we will take a detailed look at what welding with 7018 entails and how it can benefit your project.

7018 is an electrode that is commonly used for welding low carbon steels. It can also be used for welding some high carbon steels as well. When using this electrode, you will want to use the DC+ current setting.

This means that the current will flow in one direction only. The reason for this is because it helps to reduce the amount of spatter that is produced during the welding process. You will also want to make sure that you have a good ground connection when using this electrode so that you do not get any arcing during the process.

One of the benefits of welding with 7018 is that it produces a very smooth and clean bead while still providing good penetration into the metal being welded. This makes it ideal for applications where aesthetics are important, such as in architectural projects or even some pieces of jewelry. Additionally, this electrode produces little slag, meaning there is less cleanup required after welding than with other types of electrodes.

If you are looking for an electrode that will provide good results on both low and high carbon steels, then 7018 is a great option for you to consider.

How to Weld Tool Steel

Tool steel is a type of carbon steel that is well-suited for making tools. It has a high carbon content (usually between 0.6% and 1.4%), which gives it good hardness and wear resistance. However, tool steel also has a high chromium content (around 18%), which gives it good corrosion resistance.

There are many different types of tool steel, each with its own properties and applications. The most common types are:

Water-hardening tool steel: This type of tool steel is often used for cold working applications such as punches, dies, and cutting tools.

It can be hardened by quenching in water or oil.

Oil-hardening tool steel: This type of tool steel is often used for hot working applications such as forging and stamping. It can be hardened by quenching in oil or air cooling.

Air-hardening tool steel: This type of tool steel is particularly well suited for use in tools that will be shock resistant, such as hammers and chisels. It can be hardened by quenching in air or nitrogen.

Welding Tool Steel

A2 Tool Steel Rockwell Hardness

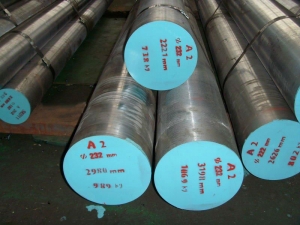

A2 tool steel is a 5% chromium alloy that is known for its high hardness and wear resistance. It is often used in tool making and other applications where a hard, durable material is needed. The Rockwell hardness of A2 tool steel is typically in the range of 60-62 HRC.

How to Harden A2 Tool Steel

A2 tool steel is a popular choice for tools and die makers, as it offers good wear resistance and toughness. However, it can be difficult to work with, as it is extremely hard. In order to make it easier to work with, you can take some steps to harden it.

First, you need to heat the steel up to around 800 degrees Celsius. Once it has reached this temperature, you will then need to quench it in oil or water. This will help to harden the steel.

Once the steel has cooled down, you can then temper it. This involves heating the steel up to around 200 degrees Celsius and then cooling it back down again slowly. This helps to improve the toughness of the steel.

With these steps, you can make A2 tool steel much easier to work with while still maintaining its excellent wear resistance and toughness properties.

Credit: www.astmsteel.com

What Temperature Should I Heat Treat A2?

A2 is a high carbon tool steel that is typically used for knives and other cutting tools. It is often heat treated to increase its hardness and wear resistance. The optimal temperature for heat treating A2 tool steel is between 1,550 and 1,650 degrees Fahrenheit.

This range of temperatures will produce the best results in terms of hardness and toughness.

Can A2 Tool Steel Be Welded?

Yes, A2 tool steel can be welded. However, because of its high carbon content, welding A2 tool steel can be difficult and it is important to use the proper welding techniques. When welding A2 tool steel, it is important to use a low carbon electrode and preheat the metal before welding.

Are Tool Steels Preheated for Welding?

Yes, tool steels are preheated for welding. The recommended preheat temperature depends on the type of tool steel, but is typically in the range of 400-1200°F (200-650°C). Tool steels with a high carbon content (> 0.60 wt%) should be heated to at least 1000°F (540°C) to prevent cracking during welding.

Does A2 Steel Need to Be Heat Treated?

No, A2 steel does not need to be heat treated. It is a air hardening steel that gets its hardness from the cold work process.

How To: A-2 Tool Steel Heat Treating

Conclusion

Assuming you would like a summary of the blog post titled “What Temp Preheat for A2 Tool Steel for Welding”, the following is a brief overview. The author begins by stating that when welding A2 tool steel, it is important to use the correct preheat temperature in order to avoid cracking. They go on to explain that the recommended preheat temperature for welding A2 tool steel is between 500-600 degrees Fahrenheit.

The author also notes that it is important to keep the weld area clean and free of contaminants before welding.