There are many ways to join two pieces of exhaust pipe together, but clamping and welding are the most common methods. Both have their benefits and drawbacks, so it’s important to choose the right method for your project. Clamping is usually faster and easier than welding, but it doesn’t create a permanent bond between the pipes.

Welding creates a stronger joint, but it can be more difficult to do properly.

If you’re working on a car exhaust system, you may be wondering whether it’s better to clamp the exhaust pipe or weld it. There are pros and cons to both methods, so it’s important to weigh your options before making a decision.

Clamping is generally quicker and easier than welding, and it doesn’t require any special equipment.

However, clamps can come loose over time, which can cause leaks. Welding provides a more permanent solution, but it’s more time-consuming and requires access to a welder.

ultimately, the best method for attaching exhaust pipes will depend on the specific circumstances of your project.

If you’re short on time or don’t have access to a welder, clamping may be the way to go. If you want a more permanent solution or are willing to take the time to weld properly, welding is usually the better option.

Exhaust Clamps Vs Welding

When it comes to repairing or replacing your car’s exhaust system, you have two main choices: exhaust clamps or welding. So, which is the better option?

Exhaust clamps are usually cheaper and easier to install than welding, but they’re not as durable.

Welding is more expensive and takes longer to do, but it creates a stronger bond that will last longer.

If you’re on a budget, then exhaust clamps may be the way to go. But if you want a more permanent fix, then welding is the better choice.

Do Exhaust Clamps Leak

If your car’s exhaust system is leaking, it could be due to a faulty exhaust clamp. Exhaust clamps are responsible for holding the exhaust system together and keeping it secure. Over time, they can become loose or corroded, which can cause leaks.

If you suspect that your exhaust clamp is leaking, you’ll need to replace it. Here’s a step-by-step guide on how to do just that:

1. Jack up your car and support it on jack stands.

This will give you access to the underside of the vehicle where the exhaust system is located.

2. Locate the offending exhaust clamp and loosen the bolts that hold it in place.

3. Remove the old exhaust clamp and install a new one in its place.

Make sure that the new clamp is tight and secure before proceeding.

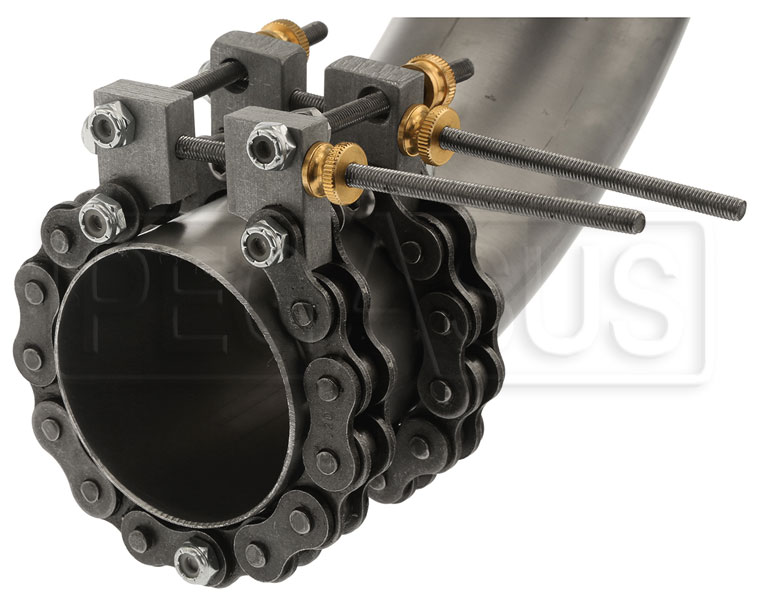

Types of Exhaust Clamps

An exhaust clamp is a device used to secure the exhaust system of a vehicle. There are many different types of clamps available, each designed for a specific purpose. The most common type of clamp is the U-bolt clamp, which is used to attach the exhaust pipe to the muffler.

Other types of clamps include V-band clamps, T-bolt clamps, and flange clamps. Each type of clamp has its own advantages and disadvantages, so it’s important to choose the right one for your needs.

U-bolt clamps are the most popular type of clamp because they’re easy to use and they’re very effective at holding the exhaust pipe in place.

However, they can be difficult to install if you don’t have access to the underside of the vehicle. V-band clamps are another popular option because they’re easy to install and they provide a tight seal that prevents leaks. However, V-band clamps can be expensive and they’re not always necessary for smaller exhaust pipes.

T-bolt clamps are similar to V-band clamps, but they offer a more secure connection between the pipe and muffler. They’re also more difficult to install than other types of clamps, so it’s important to make sure you have all the tools you need before starting the installation process. Flange claps are typically used on larger vehicles with bigger exhaust systems.

They provide a strong connection between the pipe and muffler but can be difficult to install if you don’t have access to both sides of the vehicle.

Joining Exhaust Pipes Without Welding

Welding can be a difficult and time-consuming process, especially when working with exhaust pipes. If you’re looking for an alternative to welding, there are several ways that you can join exhaust pipes without welding.

One popular method is known as “clamping.”

This involves using a series of clamps to secure the two pieces of pipe together. Clamping is a quick and easy way to join exhaust pipes, and it’s also relatively strong. However, it’s not as strong as welding, so it’s not ideal for all applications.

Another option is to use a sealant or adhesive. This will create a seal between the two pieces of pipe, which will prevent leaks. Adhesives are typically weaker than welds, so they’re not recommended for high-stress applications.

However, they’re much easier to apply and don’t require any special equipment.

If you need a strong joint without welding, you can try using mechanical fasteners. These include bolts, screws, and rivets.

Mechanical fasteners are stronger than both welds and adhesive seals, but they’re more difficult to install. You’ll need access to the inside of the pipe in order to install them properly.

No matter what method you choose, be sure to follow directions carefully and use proper safety precautions when joining exhaust pipes without welding!

How to Clamp Exhaust Pipes Together

Whether you’re a professional mechanic or a do-it-yourselfer, you may find yourself in need of clamping exhaust pipes together. While this may seem like a daunting task, it’s actually relatively simple with the right tools and techniques. Here’s how to do it:

1. Begin by cleaning the surfaces of the pipes that will be joined together. This will ensure that the clamp has a good grip and doesn’t slip during installation.

2. Next, align the pipes so that they fit snugly together.

If there are any gaps, use an exhaust pipe expander to fill them in.

3. Once the pipes are aligned, it’s time to install the clamp. Start by threading one end of the clamp through one of the holes in the flange (the metal plate that connects the exhaust system to the engine).

Then, loop it around and thread it back through the other hole in the flange. Finally, tighten down both ends of the clamp until it’s secure.

4. That’s it!

You’ve successfully installed an exhaust pipe clamp!

Best Exhaust Clamps

An exhaust clamp is a device used to attach and secure the exhaust system of an internal combustion engine to the vehicle body. Exhaust clamps are necessary to keep the exhaust system in place and functioning properly. There are many different types of exhaust clamps available on the market, so it is important to choose the right one for your vehicle.

The most common type of exhaust clamp is the U-bolt clamp, which consists of two U-shaped bolts that are tightened around the exhaust pipe. Other types of clamps include V-band clamps, T-bolt clamps, and band clamps.

How Long Will a Welded Exhaust Last

If you’re considering having your exhaust welded, you may be wondering how long the repair will last. Here’s what you need to know.

A welded exhaust can last anywhere from 2-5 years, depending on a number of factors.

The quality of the welding job is one factor that will affect how long the repair lasts. If the welder did a poor job, the exhaust could come apart sooner than expected.

Another factor that affects the longevity of a welded exhaust is how much stress is put on it.

If you regularly haul heavy loads or do a lot of stop-and-go driving, your exhaust will experience more wear and tear and may not last as long as one that isn’t subjected to those conditions.

To get the most out of your welded exhaust repair, have it done by a professional with experience in welding automotive exhaust systems. This will help ensure that it’s done properly and will last as long as possible.

Do Exhaust Clamps Work

If you’re a car enthusiast, you’ve probably wondered at one point or another whether exhaust clamps actually work. After all, they seem like such a simple solution to a complex problem. Surely they can’t be that effective, right?

Well, as it turns out, exhaust clamps are actually quite useful and can keep your car’s exhaust system running smoothly for years to come. Here’s everything you need to know about how these handy little devices work.

Exhaust clamps are designed to attach your car’s exhaust pipe to the rest of the exhaust system.

They use either a bolt-and-nut system or a quick-release lever to stay secure. Most importantly, they create a seal that prevents fumes and noise from escaping the system. This is especially important if you have an aftermarket exhaust system that is louder than stock.

So, do exhaust clamps actually work? The answer is yes! These devices are essential for keeping your car’s exhaust system functioning properly.

Without them, you would likely experience leaks and other issues that could lead to costly repairs down the road. If you’re looking for an easy way to prolong the life of your car’s exhaust system, investing in a few good quality exhaust clamps is definitely worth it.

Credit: www.pegasusautoracing.com

Should Exhaust Be Welded Or Clamped?

If you’re working on a car’s exhaust system, you might be wondering whether it’s better to weld or clamp the exhaust pipes together. Here’s a look at the pros and cons of each method so you can decide what’s best for your situation.

Welding offers a stronger connection than clamping, which is why it’s often used in automotive applications.

However, welding also requires special equipment and skills, so it’s not always an option for do-it-yourselfers. Another downside to welding is that it can cause warping and distortion if the metal gets too hot.

It’s also less likely to damage the exhaust pipes since there’s no heat involved. However, clamps don’t create as strong of a connection as welding does, so they might not be ideal for heavy-duty applications.

Is a Welded Exhaust Better?

Welded exhaust systems are believed to be better than their bolted counterparts for a number of reasons. One reason is that the welding creates a stronger, more secure bond between the parts. This can be beneficial in areas of high vibration, as it helps to prevent rattling and potential breakage.

Another advantage is that welded seams are less likely to leak, meaning that fewer repairs will be needed over time. Finally, many people believe that welded systems have a more aesthetically pleasing appearance than those with visible bolts.

Can You Put Exhaust Together Without Welding?

You can put together an exhaust system without welding, but it will be less durable and may not fit as well. You can use bolts and gaskets to hold the system together, but over time they will loosen and the system will leak. If you are looking for a long lasting, high performance exhaust system, welding is the way to go.

What is the Best Way to Weld Exhaust Pipe?

When it comes to welding exhaust pipe, there are a few different ways that you can go about it. Each method has its own set of pros and cons, so it’s important to choose the right one for your particular project. Let’s take a look at some of the most popular methods for welding exhaust pipe:

MIG Welding: MIG welding is a popular choice for welding exhaust pipe because it’s relatively easy to learn and doesn’t require as much equipment as other methods. It also produces clean, strong welds. However, MIG welding can be difficult to master and isn’t always the best choice for thicker pipes.

TIG Welding: TIG welding is another popular choice for welding exhaust pipe. Like MIG welding, it produces clean welds but is also more difficult to master. TIG welders are also more expensive than MIG welders, so this may not be the best option if you’re on a budget.

Oxy-Acetylene Welding: Oxy-acetylene welding (also known as gas welding) is an older type of welding that uses a flame instead of an electrical arc to create the weld. This method can be used on any type of metal, including thicker pipes, but it requires more skill and experience than MIG or TIG welding.

Welding vs Clamping Your Exhaust

Conclusion

If you’re working on a car exhaust system, you might be wondering whether it’s better to clamp the pipes together or weld them. There are pros and cons to both methods, so it’s important to weigh your options before deciding which one is right for you.

Clamping is generally quicker and easier than welding, and it doesn’t require any special equipment.

However, clamps can come loose over time, causing exhaust leaks. Welding creates a permanent connection that won’t leak, but it takes longer and requires more skill.

So, which is the best method?

It depends on your needs and preferences. If you want a quick repair that will hold up for a while, clamping is probably the way to go. If you need a stronger connection that won’t leak, welding is the better option.