Welding inspection tools are used to check the quality of a weld. There are many different types of welding inspection tools, each with its own purpose. The most common welding inspection tool is a visual inspection tool, which is used to look for defects in the weld.

Other welding inspection tools include x-ray machines, ultrasonic testers, and magnetic particle inspectors.

- 1) Inspect the welding area for any potential hazards

- 2) Don all the necessary personal protective equipment (PPE)

- 3) Set up your welding machine according to the manufacturer’s instructions

- 4) Connect the ground clamp to a clean, metal surface on the workpiece

- 5) Select the appropriate electrode and insert it into the holder

- 6) Strike an arc and weld according to your qualifications

- 7) Inspect your welds visually and with tools such as a magnifying glass, borescope, or ultrasonic thickness gauge per AWS standards

Welding Inspection Tools List

Welding inspection tools are used to ensure the quality of welds. They can be used to check for defects, measure dimensions, and verify the strength of welds. There are a variety of welding inspection tools available, each with its own purpose.

Here is a list of some of the most common welding inspection tools:

1. Visual Inspection: A visual inspection is the simplest and most common type of welding inspection. It involves looking at the welds to check for any defects.

This can be done with the naked eye or with magnifying glasses or a microscope.

2. Dye Penetrant Testing: Dye penetrant testing is another common type of welding inspection. It involves applying a special dye to the welds and then using a UV light to look for any cracks or defects.

3. Magnetic Particle Testing: Magnetic particle testing is another way to check for cracks or other defects in welds. It involves applying a magnetic field to the area being tested and then looking for any irregularities in the magnetic field.

4. X-ray Testing: X-ray testing is another form of nondestructive testing that can be used to inspect welds.

It involves using X-rays to look for any hidden flaws in the welds.

Welding Inspection Tools Pdf

Welding is a process of joining two materials, usually metals or thermoplastics, by using high heat to melt the materials and create a strong joint. Welding inspection is the process of checking welds for defects such as cracks, porosity, incomplete fusion, and incorrect geometry. There are many different welding inspection tools available to help with this process.

Some of the most common tools include visual inspection, dye penetrant testing, ultrasonic testing, and X-ray testing.

Welding Inspection Tool Kit

As a welder, having a good welding inspection tool kit is important. It can help you ensure that your welds are of the highest quality and meet all industry standards.

A welding inspection tool kit typically includes a caliper, micrometer, borescope, and digital camera.

These tools allow you to measure the thickness of your welds, check for defects, and document your work.

Using a caliper, you can measure the width of your weld bead. This is important because it helps you ensure that your weld is the correct size.

If it’s too small, it may not be strong enough. If it’s too large, it may be difficult to finish the weld without burning through the metal.

A micrometer measures the depth of your weld bead.

This is important because it helps you control penetration. Too much penetration can cause problems with warping or cracking, while too little penetration can result in a poor bond between the metals being joined.

A borescope allows you to inspect your welds from the inside out.

This is especially helpful for checking for porosity (tiny holes) or other defects that might not be visible to the naked eye.

Finally, a digital camera can be used to document your work and provide visual evidence of high-quality welding. This is especially useful if you’re working on a project that will require third-party inspection or if you simply want to keep a record of your progress over time.

How to Use Welding Gauge Pdf

Welding gauges are an essential part of the welding process, allowing welders to ensure that their work is up to par. There are a few different types of welding gauges available on the market, but the most popular and useful type is the pdf welding gauge. This guide will explain how to use a pdf welding gauge properly in order to get accurate readings.

First, it is important to understand how a pdf welding gauge works. These gauges use sensors that detect changes in magnetic fields in order to take measurements. The software then translates these measurements into numbers that can be read by the user.

In order to take accurate readings, it is important that the sensors are placed correctly on the metal being welded.

Next, users need to calibrate their pdf welding gauges. This process ensures that the readings taken by the gauge are accurate.

To do this, welders should create a test piece that they know has been properly calibrated beforehand. Once they have created this test piece, they can place their sensor on it and follow the instructions provided by the software in order to calibrate their own devices.

Finally, once everything is set up and ready to go, taking readings with a pdf welding gauge is simple.

Welders just need to hold down the button on their device until it beeps or vibrates – this indicates that a reading has been taken successfully. After taking multiple readings from different areas of their workpiece, welders can compare these values to determine if any adjustments need to be made before continuing with their project .

How to Use Welding Gauge

Welding gauges are tools that help welders ensure that their work meets the proper standards. There are many different types of welding gauges, but they all serve the same purpose: to help you create accurate, precise welds. Here’s a quick guide on how to use welding gauges:

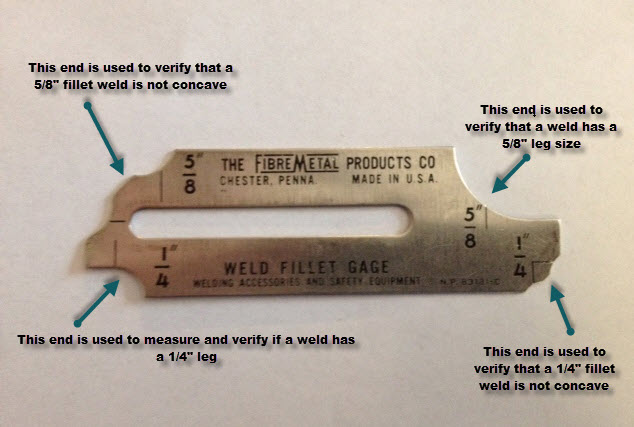

First, identify the type of gauge you need. There are three main types of welding gauges: fillet, throat, and root. Fillet gauges measure the size of the fillet (the V-shaped area between two pieces of metal), while throat and root measures gauge the depth of penetration.

Once you’ve identified the type of gauge you need, it’s time to take measurements. For most welds, you’ll want to take three separate measurements: one at the start of the weld, one in the middle, and one at the end. This will give you an accurate idea of how deep your weld is penetrating and how large your fillet is.

When taking measurements, be sure to hold the welding gauge perpendicular to the surface of the metal. This will give you the most accurate reading possible. Once you have your readings, note them down so you can reference them later.

As a general rule of thumb, your weld should penetrate at least 1/3 its thickness for a good bond. If it’s less than that, consider redoing the weld or adding more filler material. And finally, always make sure to double-check your work with a second set of eyes (or another welding gauge) before calling it quits!

Cambridge Gauge Welding

If you’re looking for a reliable, high-quality welding service in the Cambridge area, look no further than Cambridge Gauge Welding. We specialize in all types of welding, including MIG, TIG, and Stick welding. We also offer a wide range of other services such as plasma cutting, oxy-fuel cutting, and more.

No matter what your welding needs are, we can help.

We want you to feel confident that your project is in good hands when you choose Cambridge Gauge Welding. Welding is an important process for many industries, and we are proud to be able to offer our services to businesses in the Cambridge area. If you’re looking for a reliable welding company that will get the job done right, give us a call today at (xxx) xxx-xxxx.

Types of Welding Inspection

Welding inspection is a critical process in ensuring the quality of welded joints. There are many different types of welding inspections, each with its own advantages and disadvantages. Here is a brief overview of the most common types of welding inspection:

Visual Inspection: Visual inspection is the most basic form of weld inspection. It involves looking at the welded joint to check for defects such as cracks, porosity, or incomplete fusion. This type of inspection is quick and easy to perform, but it can be difficult to detect some types of defects.

Radiographic Inspection: Radiographic inspection uses X-rays or gamma rays to examine welds for defects that are not visible to the naked eye. This type of inspection is more expensive and time-consuming than visual inspection, but it can detect hidden flaws that could cause problems later on.

Ultrasonic Inspection: Ultrasonic inspection uses high-frequency sound waves to examine welds for defects.

This type of inspection is very accurate, but it is also expensive and time-consuming.

Magnetic Particle Inspection: Magnetic particle inspection uses magnetic fields to detect surface flaws in welds. This type of inspection is relatively quick and easy to perform, but it can only be used on ferrous materials.

Credit: weldinganswers.com

How Do You Do a Welding Inspection?

Welding inspection is a vital process in ensuring the quality of welded structures. There are many factors to consider when inspecting a weld, such as width, depth, angle, and alignment. A welding inspector must be able to identify defects and imperfections in order to ensure that the final product meets all safety and quality standards.

The first step in welding inspection is to visually examine the weld area for any obvious defects. If any are found, the next step is to measure the dimensions of the defect using calipers or a micrometer. Once the size of the defect has been determined, it can be classified as either a major or minor defect.

Major defects will require repair or replacement of the affected component, while minor defects can usually be ignored.

After visual and dimensional inspection, the next step is to perform a nondestructive test (NDT) on the welded joint. The most common NDT method used for welding inspection is radiographic testing, which uses X-rays or gamma rays to inspect the internal structure of the weld.

This type of testing can detect flaws that are not visible with visual inspection alone.

Once all inspections have been completed and any necessary repairs made, the final step is to apply a coating to protect the weld from corrosion. This can be done with paint or powder coating and should be applied according to manufacturer’s specifications.

How Do You Use a Welding Inspection Gauge?

A welding inspection gauge is a tool that helps welders ensure that their welds are of the correct depth. There are two main types of welding inspection gauges: those that measure the root opening of the weld, and those that measure the face width of the weld.

To use a welding inspection gauge, first determine which type of gauge you need based on the type of weld you are inspecting.If you are inspecting a butt joint, for example, you will need a root opening gauge. Place the appropriate end of the gauge against the surface of the weld and align it so that it is perpendicular to the axis of the weld. Then, simply read off the measurement indicated on the scale.

When using a face width gauge, again align it so that it is perpendicular to the axis of the weld before taking your measurement. It is important to note that both types of welding inspection gauges should be used in conjunction with each other in order to get an accurate picture of your weld’s quality.

What is the Most Commonly Used Method of Weld Inspection?

Weld inspection is the process of examining welds to ensure they meet the required standards. There are various methods of weld inspection, but the most common is nondestructive testing (NDT). NDT uses techniques that allow welds to be examined without damaging them, making it ideal for quality control purposes.

Common NDT methods used for weld inspection include visual inspection, radiographic testing, ultrasonic testing and magnetic particle testing. Each of these methods has its own advantages and disadvantages, so it’s important to choose the right one for the job at hand.

Visual inspection is perhaps the simplest form of NDT, as it simply involves looking at the welds with the naked eye or using a magnifying glass.

This method is cheap and quick, but it can be limited in its effectiveness, especially if flaws are small or difficult to spot.

Radiographic testing involves taking X-rays of the welds and examining them on film. This method can detect smaller defects than visual inspection, but it is more expensive and time-consuming.

Ultrasonic testing uses high-frequency sound waves to examine welds for defects; this method can detect even very small flaws, but it requires special equipment and trained personnel to operate it effectively.

Magnetic particle testing is another common NDT method used for inspecting ferrous materials such as steel and iron. In this technique, a magnetic field is applied to the material and tiny particles are used to highlight any areas where there are breaks in the magnetic flux (indicating a flaw in the material).

Magnetic particle testing is relatively quick and easy to set up, but like ultrasonic testing, it requires specialised equipment and trained personnel to carry out properly.

What are the Three Stages of Welding Inspection?

There are three main stages of welding inspection: pre-weld, in-progress, and post-weld.

Pre-weld inspection is vital to ensuring the quality of the weld. It includes checking the materials to be used, the surface preparation, and the fit-up of the joint.

This stage also involves creating a Welding Procedure Specification (WPS), which will be used as a guide during welding.

In-progress inspection is conducted while welding is taking place. The welder must adhere to the WPS, and inspectors will check for any defects that may occur.

This stage also involves monitoring the progress of the weld to ensure it meets all specifications.

Post-weld inspection is conducted after welding is complete. Inspectors will check for any defects that may have occurred during welding, and they will also verify that all specifications were met.

If any repairs are necessary, they will be made at this time.

Welding Inspection Equipments Use By Welding Inspector.

Conclusion

If you’re interested in welding, then you’ll need to know about the different welding inspection tools. These tools are used to check the quality of welds and make sure they meet standards. There are a few different types of welding inspection tools, including magnetic particle inspection, ultrasonic testing, and visual inspection.