Most people don’t think about how important their hitch ball is until they’re stuck on the side of the road with a loose one. A loose hitch ball is more than just an inconvenience, it’s actually dangerous. If your hitch ball isn’t properly tightened, it can come loose while you’re driving and cause serious damage to your vehicle or even injure someone.

Luckily, there’s an easy way to tighten a hitch ball without a torque wrench.

- Park your vehicle on a level surface and set the parking brake

- Place a jack under the trailer tongue to take some of the weight off of the hitch ball

- Unscrew the retaining nut that secures the hitch ball to the shank using an open-end wrench or socket wrench

- Remove any washers that may be between the hitch ball and retaining nut

- Tighten the retaining nut by hand as much as possible, then use an impact wrench or ratchet to finish tightening it until it is snug against the hitch ball

How to Guess Torque Without Torque Wrench

If you’re working on a car, or really any project that involves bolts, it’s important to know how tight to make them. Too loose and things will rattle and fall apart. Too tight and you risk stripping the threads or breaking the bolt.

The answer is torque, which is a measure of how much turning force is required to achieve a certain level of tightness on a fastener.

Most people use a torque wrench to get this done right. But what if you don’t have one?

Can you guess torque without using a torque wrench?

The short answer is yes, but it’s not going to be exact. And depending on how critical the application is, that might not be good enough.

But if you’re in a bind and need to get something tightened down without a torque wrench, here are some tips on how to do it.

First, note that there are two types of torque: clamping force and preload tension. Clamping force is what keeps two surfaces together so they don’t move relative to each other (think about holding your hand around a basketball).

Preload tension adds an extra amount of force so that when load is applied (like when someone sits in a chair), the joint doesn’t slip or loosen up over time (think about tightening the nut on a bolt). Most applications require both clamping force and preload tension.

To estimate clamping force without using a torque wrench, try this method:

With your fingers, tighten the bolt until you can just barely twist it any more with your fingers—basically until it starts getting hard to turn. Then take your thumb and index finger and squeeze them together as hard as you can for 10 seconds while maintaining contact with the bolt head . After 10 seconds , multiply that number by 4 .

That’s approximately how many Newton-meters (Nm) of clamping force you’ve generated .

For example : If I can just barely twist the bolt with my fingers after 5 seconds of turning , then I would multiply 5 x 4 = 20 Nm . This isn’t an exact science , but according to experts , it should get you within plus or minus 30% of the actual value .

Estimating preload tension requires knowing the diameter of the fastener being used because preload tension varies based on fastener diameter .

Estimating Torque by Hand

If you’re a do-it-yourselfer, you might find yourself in a situation where you need to estimate torque by hand. Whether you’re estimating the torque required to remove a stubborn bolt or to install a new one, there are some simple steps you can follow to get an accurate estimate.

To start, it’s important to understand that torque is a measure of rotational force.In other words, it’s the amount of force required to rotate an object about an axis. When estimating torque by hand, you’ll need to take into account the length of the lever (i.e., the distance from the fulcrum point to the point of application), as well as the applied force. Here’s a quick formula you can use: Torque = Lever Length x Applied Force.

For example, if you’re using a wrench that’s 1 foot long and applying 10 pounds of force at the end of the wrench, your estimated torque would be 10 foot-pounds (1 ft x 10 lb). Keep in mind that this is just a rough estimate – for more precise results, it’s always best to consult with a professional or use specialized equipment designed for measuring torque. But if all you have is a ruler and some basic knowledge of physics, this method will definitely help you out in a pinch!

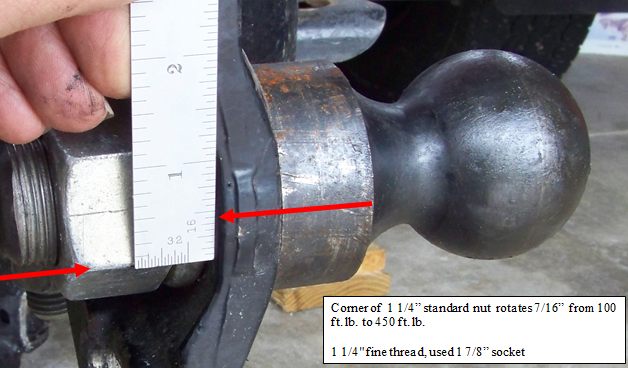

How to Torque Hitch Ball to 450 Ft Lbs

If you’re towing a trailer, it’s important to know how to properly torque the hitch ball. After all, you don’t want your trailer coming unhitched while you’re on the road! Here’s a step-by-step guide on how to torque a hitch ball to 450 ft lbs:

1. Place the wrench on the nut of the hitch ball and hold it in place.

2. Use another wrench to turn the bolt clockwise until it is tight. Make sure not to over-tighten it!

3. Once the bolt is tight, use the first wrench to turn the nut clockwise until it is snug against the bolt head. Again, be careful not to over-tighten.

4. Finally, use a torque wrench to tighten the nut and bolt combination to 450 ft lbs of torque.

How to Tighten Trailer Hitch

Assuming you are talking about a trailer hitch for a car:

First, you will want to make sure that the Hitch is properly mounted to the vehicle. Next, use a lug wrench to tighten all of the bolts on the hitch.

Once all of the bolts are tight, use a torque wrench to ensure that they are all tightened to the proper specifications. Finally, check that the hitch is level and adjust accordingly if necessary.

How to Secure a Hitch Ball

If you’re towing a trailer, chances are you’ll need a hitch ball. A hitch ball is a simple device that attaches to the end of your tow bar and provides a mating point for the coupler on your trailer. While it may seem like a small and insignificant part of your towing setup, it’s actually one of the most important.

After all, without a hitch ball, you wouldn’t be able to couple your trailer to your tow vehicle!

While hitch balls may seem pretty straightforward, there are actually a few things you need to know in order to choose the right one and use it correctly. In this blog post, we’ll cover everything you need to know about hitch balls so that you can be confident in selecting and using the right one for your application.

First things first: what size hitch ball do I need? Hitch balls come in various sizes, which are determined by two measurements: the shank diameter and the shank length. The shank diameter is simply the width of the cylindrical portion of the hitch ball (where it mounts into the tow bar) while the shank length is measured from underneath the head of the hitch ball to where it meets up with the tow bar.

To figure out what size hitch ball you need, simply measure these two dimensions on your existing setup (or on your planned tow bar if you don’t have one yet). Once you know these numbers, finding a replacement or new hitch ball is easy – just make sure to match both numbers! In terms of material, most hitch balls are made from either steel or stainless steel.

Steel Hitch Balls are less expensive but more prone to rusting over time whereas Stainless Steel Hitch Balls cost slightly more but will last longer due to their corrosion-resistant properties. If budget is a concern, go with a steel option – otherwise we recommend going stainless for longevity purposes.

Torque Wrench for Hitch Ball

If you’re looking for a torque wrench to help you with your hitch ball, there are a few things you need to know. First, you need to make sure that the torque wrench you purchase is compatible with the size of your hitch ball. Second, you need to determine how much torque is required to properly secure your hitch ball.

The amount of torque required will vary depending on the weight of your trailer and the type of hitch ball you’re using. Lastly, remember to always follow the manufacturer’s instructions when using a torque wrench.

How to Tighten Cylinder Head Without Torque Wrench

If your cylinder head is loose, you may be able to tighten it without a torque wrench. Here’s how:

First, remove the spark plugs and turn the engine over by hand to make sure there are no valves sticking open.

Next, remove the rocker arms (if applicable) and any other components that may be in the way.

Now, using a socket and ratchet or impact wrench, tighten the cylinder head bolts in a criss-cross pattern until they’re snug. Then, using a torque wrench, tighten each bolt to the specified torque rating.

Finally, reassemble everything and start the engine to check for leaks.

If you don’t have a torque wrench or your cylinder head is still leaking after following these steps, then it’s time to take it to a mechanic. Loose cylinder heads can cause big problems if not fixed properly!

Tightening Trailer Hitch Ball

Assuming you would like a blog post discussing how to properly tighten a trailer hitch ball:

Most people know that you need a strong and secure connection between your vehicle and trailer when hauling. This important connection is made at the hitch, where the trailer’s coupler attaches to the hitch ball mounted on your vehicle.

It is very important that this connection be tight in order to avoid any accidents while on the road. If the trailer becomes disconnected from the vehicle, it could cause serious damage or injury.

There are two ways to ensure that your hitch ball is properly tightened.

The first way is to use a torque wrench. This will allow you to apply the perfect amount of pressure to achieve a secure connection. Make sure to follow the manufacturer’s instructions when using a torque wrench, as too much pressure can damage the threads on either the hitch ball or coupler.

The second way to tighten a trailer hitch ball is by using an impact wrench. This method is much easier than using a torque wrench, but it can be less accurate. If you choose to use an impact wrench, make sure not to overtighten the connection as this could strip the threads or damage other parts of the system.

Again, always consult your manufacturer’s instructions when using an impact wrench on your trailer hitch ball. By following these simple tips, you can be confident that your trailer will stay securely attached during even the longest journey!

Credit: www.sunlineclub.com

Do I Need a Torque Wrench for Hitch Ball?

No, you don’t need a torque wrench for hitch ball. The torque is simply the amount of force required to turn or rotate an object.

What Can I Use If I Don’T Have a Torque Wrench?

A torque wrench is a tool that is used to apply a specific amount of force to a bolt or other fastener. It is used to ensure that the fastener is tightened to the correct specification. If you do not have a torque wrench, you can use a regular wrench, but you will not be able to apply the same level of precision and accuracy.

How Do You Tighten a Towball?

When you are towing a trailer, the last thing you want is for the towball to come loose. This can not only be dangerous, but it can also damage your vehicle and the trailer. Luckily, tightening a towball is a relatively easy process that anyone can do with the right tools.

The first step is to locate the nut on the back of the towball. This is usually located under a protective cover. Once you have found it, use an appropriate wrench to loosen it.

Next, take a look at the condition of the washer. If it is damaged or bent in any way, it should be replaced before proceeding.

Now, simply tighten the nut until it is snug against the washer.

Be careful not to over-tighten as this could damage both the towball and your vehicle’s receiver hitch. That’s all there is to it! By following these simple steps, you can ensure that your towball will stay securely in place while you’re on the road.

How Tight Does Ball Need to Be on Hitch?

It is important to make sure that the ball on your hitch is tight in order to prevent any accidents while you are driving. If the ball is not tight, it could come loose and cause the trailer to detach from the vehicle. This could lead to serious injuries or even death.

It is best to check the tightness of the ball before each drive, and if you notice that it is starting to loosen, tighten it up with a wrench until it is snug.

How To Install A Trailer Hitch And Ball On Your Truck Harbor Freight

Conclusion

If you’re wondering how to tighten a hitch ball without a torque wrench, wonder no more! This handy guide will show you how to do it in just a few easy steps. First, find a socket that fits snugly over the top of the hitch ball.

Next, use an extension bar to reach the nut on the underside of the trailer coupler. Finally, use a ratchet to tighten the nut until it’s snug. That’s all there is to it!

With these simple tips, you’ll be able to properly secure your trailer without any fuss.