It is important to torque a bolt without a torque wrench in order to prevent damage to the bolt or threading. First, determine the appropriate amount of torque required for the application. Second, hold the bolt head with an adjustable wrench and tighten until there is resistance.

Finally, use a cheater bar if needed to achieve the desired torque.

- Before torqueing a bolt, ensure that the threads are properly lubricated with either oil or grease

- This will help prevent damage to the threads and allow for proper torqueing

- Place the bolt in the desired location and hand-tighten it until snug

- Do not use power tools to do this as it can damage the threads

- Once the bolt is snug, use a wrench to finish tightening it until you reach the desired torque

- Make sure to hold the wrench at the end of its handle to apply maximum torque without damaging the wrench itself

Estimating Torque by Hand

If you’re a mechanical engineer, sooner or later you’ll need to estimate torque by hand. There are many reasons why you might need to do this: maybe you’re in the field and don’t have access to fancy tools, or maybe you’re just trying to get a quick sense of how much force is required for a given task. Whatever the reason, it’s useful to know how to estimate torque without any special equipment.

The first thing to understand is that torque is a rotational force; it’s the force that causes an object to rotate around an axis. To calculate torque, you need two things: the magnitude of the force (F) and the lever arm (l). The lever arm is simply the distance from the axis of rotation to where the force is applied.

You can think of it like a wrench: the longer the wrench, the more leverage it has, and thus more torque.

Here’s the formula for estimating torque:

T = F * l

So if we know the magnitude of the force and lever arm, we can easily calculate torque. Let’s look at an example. Suppose we want to estimate the amount of torque required to lift a heavy object.

We know that lifting objects requires quite a bit of force, so let’s say our estimated force is 1000 N (newtons). And since we’re lifting something heavy, we’ll also assume that our lever arm is relatively long; let’s say 1 meter. So our calculation would be:

How to Torque a Bolt to 400 Ft-Lbs

If you’re looking to torque a bolt to 400 ft-lbs, there are a few things you’ll need to do. First, make sure you have the right tools for the job. You’ll need a torque wrench that can handle up to 400 ft-lbs of torque.

Next, find the appropriate size socket for your bolt. Once you have those two things, you’re ready to get started.

To begin, put the socket on the end of your torque wrench and then attach it to the bolt.

Once it’s securely in place, start tightening the bolt until you reach 400 ft-lbs of torque. Be careful not to over tighten it – stop as soon as you hit 400 ft-lbs. That’s all there is to it!

Just remember to always use caution when working with tools and bolts – if done incorrectly, serious injury could occur.

Make Your Own Torque Wrench

If you’re a car enthusiast, or even if you just do your own vehicle maintenance, having a torque wrench is pretty much essential. They’re not too expensive to buy, but if you’re the DIY type, why not make your own? It’s actually not that difficult, and in this post we’ll show you how.

You’ll need a few things to get started: a length of pipe (preferably steel), some nuts and bolts, washers, and a handle (a piece of wood or metal will work fine). You’ll also need a way to measure the torque – either an analog gauge or digital readout will do. Once you have all your materials gathered, it’s time to start building.

Cut two pieces of pipe, each about 12″ long. These will be the “arms” of your wrench. Next, take one of the arms and drill a hole near one end. This hole should be big enough to accommodate the bolt that will hold everything together.

Do the same thing with the other arm piece. Now it’s time to assemble everything. Thread the bolt through one of the arms, then add on a washer and nut.

Tighten this down so that the arm is securely attached to the bolt. Repeat with the other arm piece. At this point you should have something that looks like a giant letter “T”.

Now it’s time to add the handle. Drill another hole in each arm piece, this time near the opposite end from where you drilled before (the holes should be perpendicular to each other). Thread your handle through these holes and secure with another washer and nut on each side.

Again, tighten these down well so that everything is secure. The last step is to calibrate your wrench by attaching it to whatever you’ll be using it for (a socket set is ideal) and measuring the amount of torque required for proper operation according to manufacturer specifications . Once you know how much torque is required , simply adjust your wrench accordingly . And there you have it – your very own DIY torque wrench!

How Much Torque Can You Apply by Hand With a Wrench

If you’ve ever wondered how much torque you can apply by hand with a wrench, the answer may surprise you. It turns out that the average person can generate between 30 and 40 foot-pounds of torque with nothing more than their bare hands.

Of course, this number will vary depending on your individual strength and size, but it’s still impressive nonetheless.

So next time you’re feeling extra strong, go ahead and give it a try! Just be careful not to overdo it – remember, safety first!

20 Ft Lbs Without Torque Wrench

If you’re working on a project that requires precise torque measurements, you may be wondering if it’s possible to achieve 20 ft-lbs without using a torque wrench. The answer is yes – but it’s important to understand the risks involved in doing so.

Without a torque wrench, it can be very difficult to achieve an accurate measurement of torque.

This means that there’s a greater risk of overtightening or undertightening fasteners, which could lead to serious problems down the line. Additionally, not using a torque wrench puts additional strain on your muscles and joints, which could lead to injuries if you’re not careful.

If you absolutely must achieve 20 ft-lbs of torque without using a torque wrench, there are a few methods you can use.

First, try using a socket extension with a clicker-type mechanism built in. These extensions will give you an audible indication when the desired amount of force has been reached.

Another option is to use two identical wrenches – one for each hand – and apply pressure until the wrenches slip out of your hands at the same time.

This method isn’t as accurate as using an extension with a clicker mechanism, but it’s better than nothing.

Finally, if you have access to calibrated weights, you can place them on top of the fastener until the desired amount of force has been achieved. Again, this method isn’t perfect, but it can help get you close to the desired measurement.

Whatever method you choose, just remember that working without a torque wrench is risky business. Make sure you take all necessary precautions to avoid injuring yourself or damaging your project!

80 Ft-Lbs Without Torque Wrench

If you’re a car enthusiast, you know that one of the most important tools in your toolbox is a torque wrench. But what do you do when you don’t have one on hand? Is it possible to tighten bolts without a torque wrench?

The answer is yes, but it’s not as simple as just using any old wrench. You’ll need to use a little bit of math and some estimation to make sure you’re applying the correct amount of force.

Here’s a quick guide on how to tighten bolts without a torque wrench:

1. Find out the bolt’s thread pitch. This is usually listed in either millimeters or inches. For example, M12 x 1.5 means the thread pitch is 1.5 millimeters.

2. Use a wrench that fits the bolt snugly. A loose-fitting wrench will cause more slippage and make it harder to estimate the right amount of force to apply.

3. Calculate the required force by multiplying the bolt’s thread pitch by its width (in millimeters).

For example, if you’re working with an M12 x 1.5 bolt, you would multiply 12 by 1.5, which equals 18 Newton meters (Nm) of force required for proper tightening.. To convert from Nm to ft-lbs.

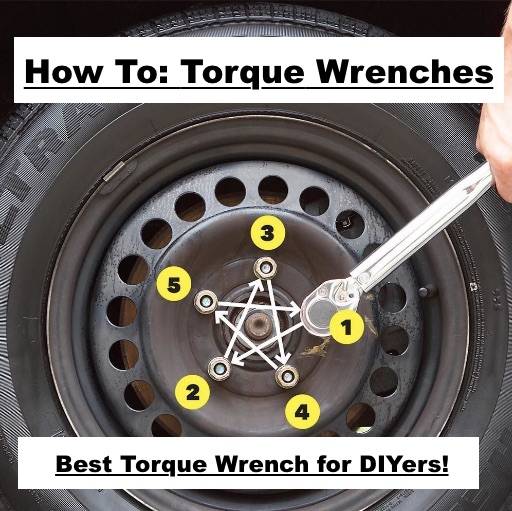

How to Use a Torque Wrench

A torque wrench is a tool that allows you to apply a specific amount of force to a bolt or nut, which is essential when working with delicate machinery. If you’re not familiar with how to use one, don’t worry – it’s actually quite simple! Here’s a quick guide on how to use a torque wrench:

First, select the correct size of wrench for your bolt or nut. A torque wrench typically has two units of measurement – Newton meters (Nm) and foot-pounds (ft-lb). Make sure you know which unit of measurement your project uses before proceeding.

Next, set the desired amount of force on the torque wrench. Again, make sure you’re using the correct units of measurement! Once the desired force is set, simply tighten the bolt or nut until it reaches that level of force.

And that’s all there is to it! Using a torque wrench is easy once you get the hang of it, and it will help ensure that your projects are completed correctly and safely.

How to Set Torque Wrench

When it comes to torque wrenches, there are two main types: those that measure in Newton meters and those that measure foot-pounds. The first thing you need to do when setting a torque wrench is to determine which measurement unit your wrench uses. Once you know that, simply set the desired torque level by turning the knob or adjusting the dial on the wrench until the reading matches what you’re looking for.

Some wrenches also have a release button or lever that must be engaged before usage.

Now it’s time to use the torque wrench. Place it on the fastener (bolt, nut, etc.) that you wish to tighten and ensure that the handle is pointing in the direction you want it to go when tightened (usually clockwise).

Next, pull on the handle with steady pressure until you reach the desired torque level – at this point, you should hear or feel a click indicating that the wrench has reached its limit. Do not continue trying to turn after this click; doing so can damage boththe fastener andthe wrench itself. Finally, loosen the grip onthe handle and disengage any release buttons or levers before removingthe wrench fromthe fastener.

Credit: agradetools.com

What Happens If You Dont Use a Torque Wrench?

If you don’t use a torque wrench, you may not tighten the bolts to the correct tension. This could lead to the bolts becoming loose and eventually falling out. If this happens while the vehicle is in motion, it could be extremely dangerous.

How Do You Tighten Nuts Without a Torque Wrench?

There are a few ways to tighten nuts without a torque wrench. The most common method is to use a ratchet and socket. Another way is to use pliers, an adjustable wrench, or an open-end wrench.

If you’re using a ratchet and socket, the first thing you’ll need to do is find the proper size socket for the nut you’re trying to tighten. Once you have the right size socket, attach it to the ratchet and insert it onto the nut. Then, simply turn the ratchet clockwise until the nut is tightened down.

If you don’t have a socket that will fit the nut, you can try using one of the other tools mentioned above. Pliers, adjustable wrenches, and open-end wrenches all work in basically the same way – just place the tool onto the nut and then turn it clockwise until tight.

Keep in mind that without a torque wrench, it’s difficult to know how tight to make the nut.

In general, you’ll want to make it as tight as possible without stripping or damaging either thenut orthe bolt/screw that it’s attached to. If possible, try to get another person to help hold things in place while you’re tightening down the nut so that everything stays aligned properly.

What is the Torque Value of Hand Tight?

The torque value of hand tight is different for everyone. It all depends on how strong your grip is and how big your hands are. Generally speaking, though, the torque value of hand tight is between 30 and 40 foot-pounds.

This range should be sufficient for most applications where you need to secure a fastener by hand.

Do You Really Need to Use a Torque Wrench?

A torque wrench is a tool that applies a specific amount of force to a fastener, such as a nut or bolt. It is used to ensure that the fastener is tightened to the correct level of tension. The advantage of using a torque wrench is that it helps to prevent overtightening, which can damage the fastener or the component it is securing.

There are many circumstances where using a torque wrench is advisable. For example, when working with delicate electronics, you would not want to risk damaging them by overtightening screws. Similarly, when assembling furniture or machinery, it is important to follow the manufacturer’s instructions regarding how tight to make each joint.

In general, any time you need to apply a precise amount of force to a fastener, using a torque wrench is the best way to go about it.

Of course, there are some situations where using a torque wrench might not be necessary. For example, if you are simply tightening up some loose screws around the house, you probably don’t need to go out and buy a special tool.

However, if you are doing any sort of work where precision is important – such as automotive repairs – then investing in a good quality torque wrench is definitely worthwhile.

How to torque without a torque wrench

Conclusion

If you’re working on a project that requires bolts to be tightened to specific torque values, you may not have a torque wrench on hand. But don’t worry – there are other ways to get the job done.

First, find the recommended torque value for the bolt in question.

This will usually be listed in Newton-meters (Nm), but you can also find it in foot-pounds (ft-lb). Once you have the value, use a simple calculator to convert it to pounds-force (lbf).

Next, twist the bolt until it’s tight using your fingers or a small wrench.

Once it’s tight, continue twisting it another quarter turn. This will give you a good approximation of the correct torque value.

Of course, this method is not as accurate as using a torque wrench.

But in a pinch, it’ll do the trick!