If you have an Ingersoll Rand air compressor, you may need to adjust the pressure from time to time. Here’s how to do it:

First, find the pressure gauge on your compressor.

It will be located near the top of the unit. Second, use a wrench to turn the knob on the gauge clockwise or counterclockwise until you reach the desired pressure.

Third, check the pressure release valve to make sure it is in the correct position.

The valve should be in line with the pressure gauge when you are finished adjusting the pressure. Finally, turn on your compressor and check that the new setting is working properly.

- Check the pressure gauge to see what the current pressure is set at

- Adjust the knob or lever on the air compressor to increase or decrease the pressure as desired

- If the compressor has a maximum pressure setting, do not exceed it

- Check the pressure gauge again to make sure that the new setting is accurate

How to Adjust Cut-Out Pressure on Air Compressor

If you have an air compressor, chances are that you will eventually need to adjust the cut-out pressure. The cut-out pressure is the point at which the compressor turns off automatically. This is usually done to prevent the compressor from overworking itself and damaging the motor.

Here are some steps to take in order to properly adjust the cut-out pressure on your air compressor:

1) Locate the unloader valve on your air compressor. This is a small valve that is located near the discharge port of the compressor.

2) Adjusting the unloader valve will affect how much air is released when the compressor reaches its maximum pressure limit (cut-off pressure). Turn clockwise to reduce air release or turn counterclockwise to increase air release.

3) To test if your adjustment was successful, try running your compressor again and see if it shuts off at the correct pressures.

Make sure to check both sides of the cutoff range (e.g., if your cutoff was originally 90 psi, make sure it still kicks off at 90 psi and doesn’t go higher or lower).

How to Adjust Pressure Valve on Air Compressor

An air compressor pressure valve is a very important part of the air compressor. It is responsible for regulating the amount of air that is released into the system. If the pressure valve is not working properly, it can cause serious problems with the operation of the air compressor.

In order to ensure that your air compressor pressure valve is working properly, you will need to adjust it on a regular basis.

The first thing that you need to do in order to adjust the pressure valve on your air compressor is to find where it is located. The location of the pressure valve will vary depending on the model of your air compressor.

Once you have found the pressure valve, you will need to identify which knob or lever controls it. On most models of air compressors, there will be a small knob or lever that is located near the top of the unit.

Once you have found the knob or lever that controls the pressure valve, you will need to turn it clockwise in order to increase the amount of air that is being released into the system.

You should continue turning this knob or lever until you reach the desired level ofpressure. If you turn this knob or lever too far, it could cause damage to your air compressor so be sure not to overdo it.

The regulator on anair compressor regulates how muchair flows throughthe machine and out onto whatever projectyou’reworkingon at themoment – whetherit’sinflatinga tireor poweringa nail gun . Toadjustthe regulator ,simplyloosenwhateverknoborleveriskeepingittightand thenmoveittoanotherpositionthatwillgiveyoumore airflow . Just rememberto not makeany drasticchanges all at once – takeyour timeand experimentwithdifferent settingsuntilyoufindone thatsuitsyour needs!

Ridgid Air Compressor Pressure Switch Adjustment

If your Ridgid air compressor pressure switch is not working properly, it may need to be adjusted. Here’s how to do it:

1. First, check the pressure switch for any debris or build-up that could be causing it to malfunction.

If you find any, clean it off and try again.

2. If the pressure switch still isn’t working, you’ll need to adjust the cutoff pressure. To do this, turn the knob on the pressure switch clockwise to increase the cutoff pressure, or counterclockwise to decrease it.

3. Once you’ve adjusted the cutoff pressure, try operating your air compressor again. If it still isn’t working properly, you may need to take it to a professional for further diagnosis and repair.

How to Increase Pressure on Air Compressor

An air compressor is a device that increases the pressure of air by compressing it. The most common type of air compressor is the piston type, which uses a piston to compress the air. Other types of air compressors include rotary screw compressors and centrifugal compressors.

Air compressors are used in many different applications, such as powering pneumatic tools, inflating tires, and operating refrigeration systems. In order to increase the pressure on an air compressor, there are several things that can be done.

One way to increase the pressure on an air compressor is to increase the size of the cylinder.

This will allow more air to be compressed in each stroke of the piston, resulting in a higher overall pressure. Another way to increase pressure is to decrease the clearance between the piston and the cylinder walls. This will reduce the amount of leakage during compression, allowing for a higher final pressures.

Finally, using a shorter stroke length will also result in higher pressures, as less volume will be displaced during each stroke.

By following these tips, you can easily increase the pressure on your air compressor without having to make any major changes or adjustments. Doing so will allow you to get more work done with your pneumatic tools or inflate tires more quickly.

Ingersoll Rand Air Compressor Troubleshooting Guide Pdf

If your Ingersoll Rand air compressor isn’t working properly, don’t despair. There are several things you can do to troubleshoot the problem. This guide will walk you through some common issues and provide solutions for getting your air compressor up and running again.

One of the most common problems with air compressors is that they don’t build pressure. If your compressor isn’t building pressure, check to make sure that the intake valve is open and that there’s no blockage in the air intake filter. Also, be sure to check the unloader valve to see if it’s functioning properly.

If none of these solutions solve the problem, you may need to replace the pump or get a new air compressor altogether.

Another common issue is that the air compressor doesn’t shut off when it reaches its maximum pressure. This safety feature is important because it prevents damage to your equipment by overloading it with too much pressure.

If your compressor doesn’t shut off automatically, you’ll need to adjust the pressure switch so that it turns off at the right pressure level.

Next, check all of the electrical connections to be sure they’re tight and free of corrosion. Finally, if you have an electric-powered unit, be sure to check that circuit breaker and reset it if necessary. With these troubleshooting tips in mind, you should be able to get your Ingersoll Rand air compressor up and running again in no time!

Ingersoll Rand 185 Air Compressor Pressure Adjustment

If you own an Ingersoll Rand 185 air compressor, you may need to adjust the pressure from time to time. Here’s how to do it:

1. Locate the pressure adjustment knob on the side of the compressor.

2. Turn the knob clockwise to increase pressure, or counterclockwise to decrease pressure.

3. Check the gauge on the front of the compressor to see what your current pressure is set at. Adjust as needed until you reach your desired pressure.

4. Once you’ve reached your desired pressure, turn off the compressor and disconnect it from power.

How to Adjust Pressure on Campbell Hausfeld Air Compressor

If you own a Campbell Hausfeld air compressor, you may need to adjust the pressure from time to time. Here’s how to do it:

First, locate the pressure regulator knob on the side of the air compressor.

It should be clearly labeled.

Turn the knob clockwise to increase the pressure or counterclockwise to decrease it. You will feel a resistance when you turn the knob, so don’t force it.

Once you’ve set the desired pressure, tighten the knob by turning it clockwise until it stops. That’s all there is to it!

Air Compressor Pressure Switch How It Works

An air compressor pressure switch is a safety device that helps regulate the amount of pressure in an air compressor. It is typically installed near the air compressor tank and is connected to a pressure gauge. The pressure switch monitors the amount of pressure in the tank and turns the compressor on or off as needed to maintain a safe level of pressure.

Credit: www.air-compressor-guide.com

How Do I Adjust the Pressure on My Air Compressor?

If you have an air compressor, you may need to adjust the pressure at some point. Here’s how to do it:

First, find the pressure gauge on your air compressor.

It is usually located near the top of the unit.

Next, locate the pressure regulator knob. This is usually located near the bottom of the unit.

Turn the knob clockwise to increase pressure or counterclockwise to decrease pressure.

Now that you know how to adjust the pressure on your air compressor, check the owner’s manual for your specific model to find out what range of pressures are safe for your unit.

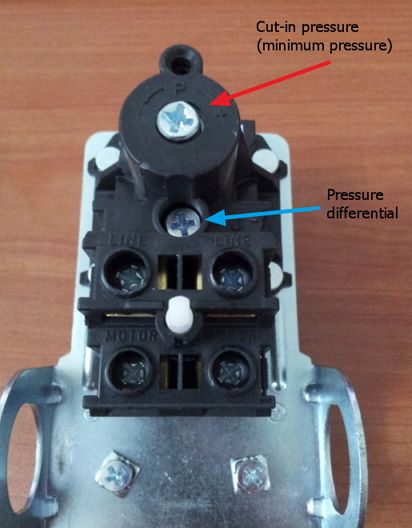

How Do You Set Cut in And Cut Out Pressure?

When it comes to setting the cut in and cut out pressure for your air compressor, there are a few things that you will need to take into consideration. The first is the type of air compressor that you have. There are two main types of air compressors, piston and rotary.

Each type of air compressor has different capabilities and therefore require different settings for the cut in and cut out pressure.

For example, if you are using your air compressor to power tools, then you will need a higher pressure than if you were just using it to inflate tires. Finally, you also need to consider the environment that you will be using your air compressor in. If it is a hot climate, then you will need a lower cut in pressure so that the motor does not overheat.

Conversely, if it is a cold climate, then you will need a higher cut out pressure so that the tank does not freeze. Now that we have covered all of the factors that go into setting the cut in and cut out pressures for your air compressor, let’s look at how to actually set these pressures. The first step is to find where your particular model’s dial or knob is located.

This should be clearly marked on the unit itself. Once you have found this dial or knob, turn it until the pointer points to 0 PSI on both sides (for most models this means turning clockwise until tight). This ensures both safety valves are open and no pressurized air is trapped inside either side of the pump head which could cause damage when restarting your unit later on down the road after storage or maintenance work.

How Do I Adjust the Regulator on My Air Compressor?

If your air compressor has an adjustable regulator, you can easily adjust the amount of air pressure that is delivered to your tools. Here’s how:

1. Locate the regulator knob on your air compressor.

This is usually located near the air outlet.

2. Turn the knob clockwise to increase the air pressure, or counterclockwise to decrease it.

3. Check the gauge on your air compressor to see what pressure you are now delivering to your tools.

Make sure not to exceed the maximum recommended pressure for your tools.

4. Once you have found the perfect setting, tighten down the regulator knob so that it doesn’t accidentally get turned while in use.

How Do You Adjust a Square D Pressure Switch on an Air Compressor?

If you have a Square D pressure switch on your air compressor, there are a few things you can do to adjust it. First, check the pressure in the tank. If it is too high or too low, you can adjust the switch accordingly.

Second, check the air compressor itself. Make sure that it is properly oiled and that all of the connections are tight. Finally, check the pressure gauge on the air compressor.

If it is not reading correctly, you may need to calibrate it.

Pressure Switch Adjustment – Ingersoll Rand 65 Gal Compressor

Conclusion

If you own an Ingersoll Rand air compressor, you may need to adjust the pressure from time to time. This is a simple process that can be done in just a few minutes. Here’s how to do it:

First, locate the pressure gauge on your air compressor. It should be located near the top of the unit.

Next, find the adjustment knob or screw.

This will usually be located next to the pressure gauge.

Turn the knob or screw until the needle on the pressure gauge points to the desired PSI (pounds per square inch). Be sure not to over-tighten it.