If your air compressor isn’t performing as well as it used to, there’s a good chance that the pilot valve needs to be adjusted. This is a relatively simple process, but it’s important to follow the steps carefully in order to avoid damaging the compressor.

- Turn off the air compressor and disconnect it from the power source

- Locate the pilot valve on the air compressor

- This is usually a small knob or lever near the pressure gauge

- Adjust the pilot valve to the desired setting

- Refer to your air compressor’s manual for specific instructions on how to do this

- Reconnect the air compressor to the power source and turn it on

Air Compressor Pilot Unloader Valve

If your air compressor has an unloader valve, you may notice that it sometimes doesn’t seem to be working correctly. The pilot unloader valve is a small device that helps to regulate the pressure in the compressor. If this valve isn’t working properly, it can cause the compressor to overheat and shut down.

Here’s what you need to know about troubleshooting a pilot unloader valve:

First, check the owner’s manual for your specific model of compressor. The unloader valve is usually located near the pressure switch or on the discharge line.

If you can’t find it, don’t hesitate to call customer service for help.

Once you’ve located the unloader valve, it’s time to test it. With the power off, slowly turn on the air supply until you hear air hissing from the valve.

This means that it’s open and functioning properly. If there’s no air coming out of the valve, it may be stuck closed and will need to be replaced.

If your compressor is still having trouble after checking and cleaning the pilot unloader valve, there could be another issue at play.

It’s always best to consult with a professional before attempting any repairs yourself.

Pilot Valve Adjustment

A pilot valve is a small, round valve located under the hood of your car. It regulates the amount of air that flows into the engine and helps to keep it running smoothly. Over time, the pilot valve can become dirty or stuck, which can cause your engine to run rough.

Luckily, adjusting the pilot valve is a relatively easy task that you can do at home with just a few tools.

-A ratchet -An extension cord -A Phillips head screwdriver

-A flathead screwdriver Start by popping the hood of your car and locate the pilot valve. It will be a small, round valve located near the front of the engine on the driver’s side.

Once you have found it, use the socket wrench to loosen the nut that holds it in place. Then, use the ratchet and extension cord to reach inside and turn the adjustment screw clockwise or counterclockwise until it is tight or loose enough to suit your needs. Finally, replacethe cover onthepilotvalveand startyourcar’sengine totestitout!

Gas Air Compressor Pilot Unloader Valve

A pilot unloader valve is a device that helps to regulate the pressure in a gas air compressor. The valve is located between the compressor and the tank, and it bleeds off excess air when the compressor is not running. This allows the compressor to start up more quickly and prevents damage to the unit from over-pressurization.

Air Compressor Continuous Run Unloader Valve

An air compressor unloader valve is a vital component of any compressed air system. It is used to release the pressure in the system when the compressor is not in use. This prevents the compressor from damage caused by over-pressurization.

The unloader valve is typically located between the air tank and the pressure switch. When the pressure switch detects that the system pressure has dropped below a certain level, it will activate the unloader valve to release some of the air from the tank. This relieves pressure on the compressor so that it can start again without damaging itself.

There are two types of unloader valves: manual and automatic. Manual valves require someone to manually open and close them when needed. Automatic valves will open and close automatically as needed, based on signals from the pressure switch.

Most unloader valves are made of durable metal materials like brass or stainless steel. They should be regularly inspected for wear and tear, and replaced if necessary.

Air Compressor Unloader Valve With Throttle Control

An air compressor unloader valve with throttle control is a great way to save energy and money on your air compressor. By using this type of valve, you can adjust the amount of air that is released from the tank when the compressor is not in use. This can help to keep your utility bills down, as well as reduce wear and tear on your equipment.

Air Compressor Unloader Valve Stuck Open

If your air compressor unloader valve is stuck open, there are a few things you can do to try and fix the problem. First, check to see if there is any debris or dirt blocking the valve. If so, clean it out and see if that fixes the issue.

If not, you may need to replace the valve itself.

Air Compressor Unloader Valve Repair

If your air compressor unloader valve is not working properly, it can cause a number of problems. The most common problem is that the compressor will not start when the pressure switch is turned on. This can be caused by a variety of things, but the most likely culprit is a faulty unloader valve.

There are a few things that you can do to repair a faulty unloader valve, but it is best to consult with an air compressor repair technician before attempting any repairs.

Credit: caddyvac.com

How Do I Adjust the Pressure Relief Valve on My Air Compressor?

The pressure relief valve on an air compressor is used to regulate the amount of air that is released from the tank. This valve is usually located at the top of the tank and is opened when the pressure in the tank reaches a certain level. The amount of air that is released can be adjusted by turning the knob on the valve.

How Do You Adjust the Pressure on a Pilot?

The pressure on a pilot is adjusted by turning the knob on the side of the seat. The knob controls a lever that opens or closes a valve in the line between the pilot and the engine.

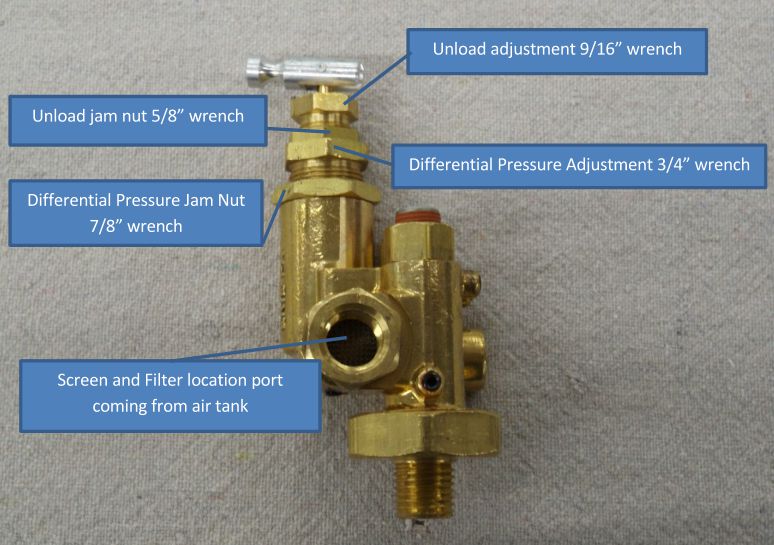

How Do You Adjust a Piloted Unloader Valve?

Piloted unloader valves are used to relieve pressure in a system by bleeding off air or fluid. They are commonly used on air compressors, but can also be used on other types of equipment. To adjust a piloted unloader valve, you will need to first identify the adjustment screw.

This is usually located on the side of the valve body. Once you have found the adjustment screw, turn it clockwise to increase the pressure relief setting or counterclockwise to decrease it.

How Does a Pilot Valve Work on a Compressor?

A pilot valve on a compressor is used to regulate the flow of air or other gas to the cylinders. The pilot valve is usually located at the back of the compressor and is opened and closed by a lever or knob. When the pilot valve is open, air flows into the cylinders and when it is closed, air does not flow into the cylinders.

How to Adjust a Pilot Valve

Conclusion

If your air compressor isn’t working properly, it might be because the pilot valve needs to be adjusted. Here’s a step-by-step guide on how to do it:

1. Shut off the power to the air compressor and disconnect any hoses that are attached.

2. Locate the pilot valve on the compressor. It is usually located near the pressure switch or regulator.

3. Use a screwdriver to turn the adjusting screw clockwise or counterclockwise until you hear a click.

This indicates that the pilot valve is now open or closed.

4. Turn on the power to the air compressor and test it out. If it still isn’t working properly, repeat steps 3 and 4 until it does work correctly.