An air compressor pressure switch is a safety mechanism that keeps the air compressor from overloading. The pressure switch is connected to the air tank and monitors the pressure in the tank. When the pressure in the tank gets too high, the switch trips and shuts off the compressor.

This prevents the compressor from working harder than it should and keeps it from overheating.

An air compressor pressure switch is a safety device that helps to regulate the amount of pressure in an air compressor. It is typically mounted on the side of the compressor and has two settings: “on” and “off.” When the pressure in the compressor reaches the “on” setting, the switch turns on the power to the motor, which then starts to pump air into the tank.

Once the desired pressure is reached, the switch automatically shuts off power to prevent over-pressurization.

Air Compressor Pressure Switch Adjustment

An air compressor pressure switch is a safety device that controls the air pressure in your compressor. If the pressure gets too high, the switch will shut off the power to your compressor. This can prevent serious damage to your equipment.

Many people don’t realize that their pressure switch needs to be adjusted from time to time. Depending on how often you use your compressor, you may need to adjust it once a year or more.

The first thing you need to do is find your air compressor pressure switch.

It’s usually located near the tank of your compressor. Once you’ve located it, you’ll need to identify the two screws that control the cut-in and cut-out pressures. The cut-in pressure is the point at which your compressor will turn on when the pressure in the tank drops below a certain level.

The cut-out pressure is the point at which your compressor will turn off when the pressure in the tank reaches a certain level.

To adjust these screw, start by turning both of them clockwise until they’re tight against their stops. This will set both pressures at their maximum levels.

Then, slowly turn each screw counterclockwise until you hear air hissing from around the edges of the switch cover plate.

240 Volt Air Compressor Pressure Switch

If you have an air compressor, chances are you will eventually need to replace the pressure switch. A pressure switch controls when the air compressor turns on and off. The switch is located between the tank and the motor, and it monitors the air pressure in the tank.

When the pressure drops below a certain level, the switch kicks on the motor to refill the tank. Once the tank is full, the switch shuts off the motor.

Single-stage switches are typically used for home air compressors because they’re less expensive. Two-stage switches are better for commercial applications because they can handle higher pressures. Most pressure switches use either 120 volts or 240 volts.

You’ll need to know what voltage your compressor uses so you can buy a replacement that matches. Some switches also come with a built-in check valve, which prevents backflow from damaging your compressor’s pump. When shopping for a new pressure switch, make sure to get one that’s rated for at least as much CFM (cubic feet per minute) as your compressor produces.

This will ensure that your compressor can keep up with demand without overworking itself and shutting down prematurely.

Air Compressor on off Switch Not Working

If your air compressor’s on/off switch isn’t working, it’s probably because the switch itself is faulty. Fortunately, this is an easy problem to fix. All you need is a new switch.

To replace the switch, first shut off the power to the air compressor. Then, remove the cover from the switch box (usually located near the motor). Inside, you’ll see two wires coming from the motor – one black and one white.

Disconnect these wires from the old switch and connect them to the terminals on the new switch.

Air Compressor Pressure Switch Repair

If your air compressor pressure switch isn’t working properly, it can be a big problem. Not only will your compressor not run properly, but you could also damage your equipment. Fortunately, pressure switch repair is relatively easy to do yourself.

In this article, we’ll walk you through the steps of troubleshooting and repairing a pressure switch on an air compressor.

First, check the power supply to the switch. Make sure that the circuit breaker is turned on and that there is power going to the switch.

If there is no power, reset the breaker and try again. If there still is no power, you may need to replace the breaker.

If any of the wires are loose, tighten them down with a screwdriver. Once you’ve checked the power and tightened any loose wires, flip the switch to see if it turns on. If it doesn’t turn on, then you’ll need to replace the switch itself.

You can purchase a replacement pressure switch at most hardware stores or online retailers that sell air compressors and related parts. Installing a new pressure switch is fairly straightforward – just remove the old one and wire in the new one according to its instructions. Once you’ve done that, test it out by turning on your air compressor and seeing if it works properly now.

Air-Compressor-Pressure-Switch-Assembly

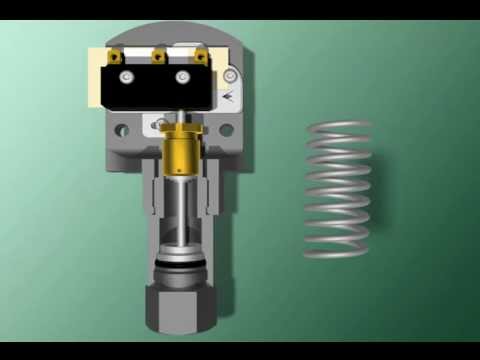

An air compressor pressure switch assembly is a device that controls the air pressure in an air compressor. It consists of a pressure switch, a pressure gauge, and a relief valve. The pressure switch turns the compressor on and off according to the preset pressures.

The pressure gauge shows the current air pressure in the system. The relief valve releases excess pressure from the system when it builds up to a certain level.

Pressure Switch Working Principle Pdf

A pressure switch is a type of switch that is activated by the pressure of a fluid. There are two types of pressure switches: those that use the force of the fluid to activate the switch, and those that use the weight of the fluid to activate the switch. The former type is called a diaphragm pressure switch, while the latter type is called a piston pressure switch.

When a diaphragm pressure switch is used, the force of the fluid presses against a diaphragm, which in turn activates a microswitch. When a piston pressure switch is used, the weight of the fluid presses against a piston, which in turn activates a microswitch.

Credit: www.youtube.com

How Does an Air Pressure Switch Work?

An air pressure switch is a type of switch that uses air pressure to open or close an electrical circuit. Air pressure switches are commonly used in industrial and commercial applications to control equipment such as fans, pumps, and compressors. When the preset air pressure is reached, the switch will activate to start or stop the equipment.

Air pressure switches can be either normally open or normally closed. A normally open air pressure switch will close when the preset air pressure is reached, while a normally closed air pressure switch will open when the preset air pressure is reached.

How Does a Pressure Switch Activate?

A pressure switch is a device that activates when the pressure of a fluid reaches a certain level. The switch can be used to control the flow of fluids, or to activate an alarm.

When the preset pressure is reached, the diaphragm moves and activates the switch.

The switch can be set to turn on at a lower pressure, and turn off at a higher pressure. This allows for precise control of fluid flow. Pressure switches are often used in pumps and compressors, where they can help to prevent damage to equipment by preventing over-pressurization.

What Does an Unloader Valve Do on a Pressure Switch?

An unloader valve is a device that is installed on a pressure switch. It allows the pressure switch to be reset without having to manually bleed off the air pressure in the system. This can be very useful in situations where the system needs to be shut down for maintenance or repair, as it eliminates the need to drain the entire system before restarting it.

How Do You Adjust a Compressor Pressure Switch?

If your compressor pressure switch is not working correctly, you may need to adjust it. Depending on the model of switch, the adjustment process will vary slightly. However, in most cases, you will need to loosen the cover screws and turn the adjusting screw with a screwdriver until the pressure is correct.

You can usually find the sweet spot by turning the screw until the compressor kicks on and off at equal intervals.

Pressure Switch Operating Principles

Conclusion

An air compressor pressure switch is a safety device that cuts off power to the motor of the compressor when the air pressure in the tank reaches a certain level. The switch is usually preset at the factory, but can be adjusted to accommodate different pressures. The switch has two connections: one for the power supply, and one for the compressor.

When the air pressure in the tank reaches the set point, a metal disk inside the switch moves, breaking the connection between power and compressor and stopping the flow of electricity.