There are many factors that go into deciding how many drill pipe slips should be used for a given job. The most important factor is the size of the hole being drilled. The deeper the hole, the more weight will be on the drill pipe and the more slips will be needed to support it.

Other factors include the type of drilling being done (e.g., horizontal vs. vertical), the amount of torque being applied, and the length of time that the drill pipe will be in use. In general, five drill pipe slips should be sufficient for most drilling jobs.

Yes, five drill pipe slips can be used for drill pipe. This is because the slips are able to grip the pipe tightly and prevent it from moving around while you are drilling. Additionally, the weight of the drill pipe is evenly distributed among the five slips, which helps to keep the pipe in place and prevents it from wobbling.

5 Inch Drill Pipe Slips Weigh

5 lbs

5 Inch Drill Pipe Slips Weigh .5 lbs

If you are in the market for a new set of drill pipe slips, then you may be wondering about the weight of the slips.

While the weight of the slips is not necessarily important, it is something that you may want to know. Here is a look at the weight of 5 inch drill pipe slips.

Each slip in a set of 5 inch drill pipe slips weighs .5 pounds.

This means that a full set of 5 inch drill pipe slips weighs 2.5 pounds.

When Moving Or Lifting Equipment With Air Hoist Or Tugger What is Appropriate Equipment to Use?*

When moving or lifting equipment with an air hoist or tugger, it is important to choose the right type of equipment for the job. There are many different types of air hoists and tuggers available on the market, so it is important to select the one that best suits your needs.

If you are moving heavy equipment, such as a large machine or piece of furniture, then you will need a powerful air hoist or tugger.These devices can lift very heavy objects and move them around easily. If you only need to move light equipment, then a smaller and less powerful device will suffice. It is also important to consider the space in which you will be using the air hoist or tugger.

If you have limited space, then a compact model may be more suitable. Alternatively, if you have plenty of space, then a larger model may be better suited to your needs. When choosing an air hoist or tugger, it is important to read the manufacturer’s instructions carefully.

This will ensure that you use the device safely and correctly.

Drill Pipe Slips Weight

Drill Pipe Slips Weight is an important factor when drilling a well. The weight of the drill pipe affects the amount of torque and drag on the drill bit, and can also affect the rate of penetration. Heavier drill pipes can cause more wear on the drill bit and reduce the life of the bit.

Drill Pipe Slips for Sale

Are you looking for a new or replacement drill pipe slip? Check out our selection of high-quality slips for sale! We have a variety of sizes and styles to choose from, so you’re sure to find the perfect fit for your needs.

Drill pipe slips are an essential part of any drilling operation. They are used to grip the drill pipe and provide support while drilling. Slips come in a variety of sizes and styles, so it’s important to choose the right one for your application.

Our selection of drill pipe slips includes options for both soft and hard ground conditions. If you’re not sure which type of slip is best for your project, our experts can help you make the selection. Contact us today to learn more about our products and get started on your next drilling project!

Credit: www.alibaba.com

What is a Drill Pipe Slip?

When working with a drill pipe, it is important to be aware of the potential for a slip. A slip occurs when the drill pipe becomes stuck and can no longer rotate. This can happen for a variety of reasons, but most often it is due to an obstruction in the wellbore.

There are two types of slips that can occur: partial and full. A partial slip only affects a portion of the drill pipe, while a full slip prevents the entire pipe from rotating. Partial slips are more common and can usually be corrected without too much difficulty.

Full slips are more serious and may require intervention from rig personnel.

If a slip does occur, it is important to stop drilling immediately and assess the situation. Attempting to continue drilling could cause further damage to the drill pipe or even result in an accident.

Once the cause of the slip has been determined, corrective action can be taken to prevent it from happening again in the future.

Is Drill String And Drill Pipe Same?

No, drill string and drill pipe are not the same. Drill string is a term used to describe the components of a drilling rig that are used to rotate the drill bit and circulate drilling fluid. This includes the drill pipe, Kelly hose, and other parts of the system.

The term “drill pipe” specifically refers to a part of the drill string that is hollow and has threaded connections on either end. It is used to connect the Kelly hose to the bottom hole assembly (BHA).

What Size is Drill Stem Pipe?

Drill stem pipe is a type of steel pipe that is used to connect the drilling rig surface equipment to the downhole drill bit. It comes in a variety of sizes, with the most common being 2 7/8 inches, 3 1/2 inches, and 4 1/2 inches in diameter.

What is the Most Common Range of Drill Pipe?

The most common range of drill pipe is 2 3/8″ to 6 5/8″, but it can vary depending on the project. The length of the drill pipe also varies, but is typically between 30 and 50 feet long.

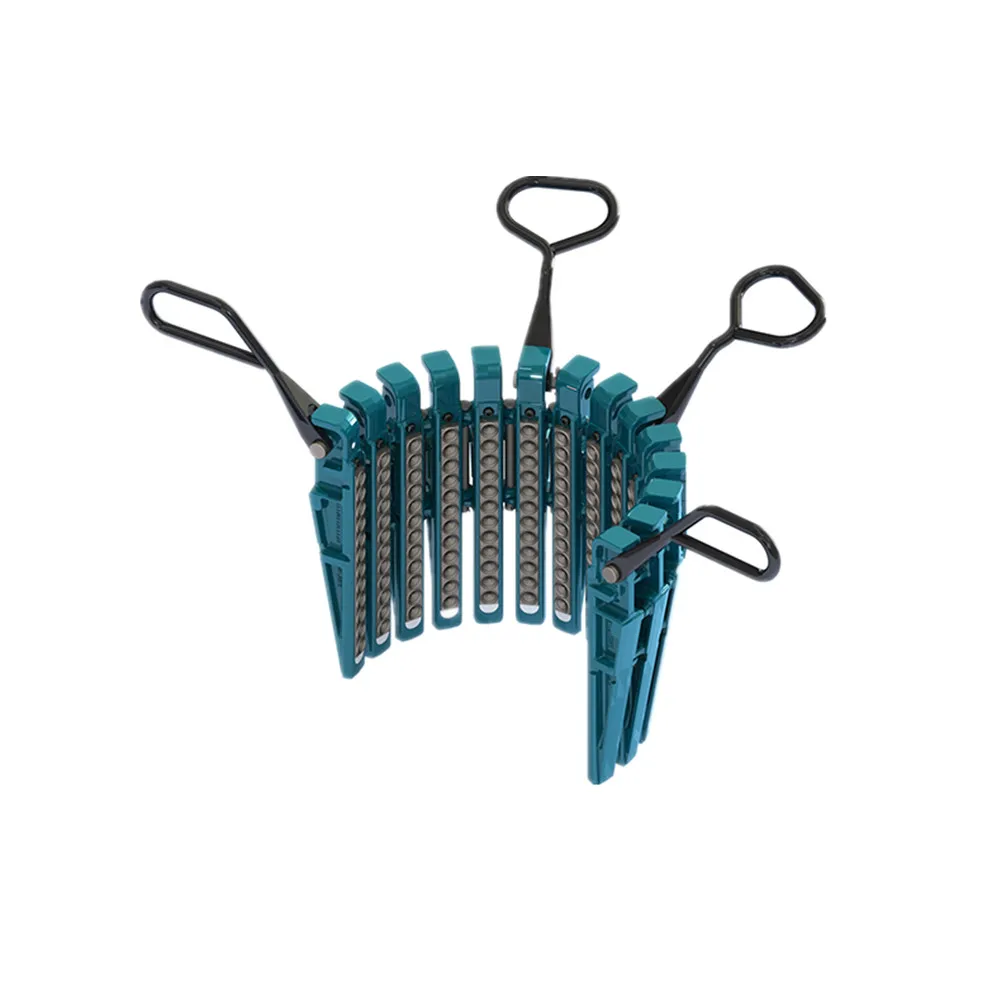

6-SLIPS DRILL PIPE

Conclusion

Can 5 Drill Pipe Slips Be Used for Drill Pipe?

It is often necessary to use a slip when drilling pipe. There are different types of slips, but the most common type is the drill pipe slip.

The drill pipe slip is designed to grip the pipe and prevent it from rotating while the drill bit is operating.

Slips come in different sizes, but the most common size is 5/8 inch. A 5/8 inch slip can be used on both 1 inch and 2 inch pipe.

There are also larger slips that can be used on 3 inch and 4 inch pipe.

The advantage of using a slip is that it prevents the need to use a wrench to hold the pipe in place while drilling. This can save a lot of time and effort when drilling large diameter pipe.